01

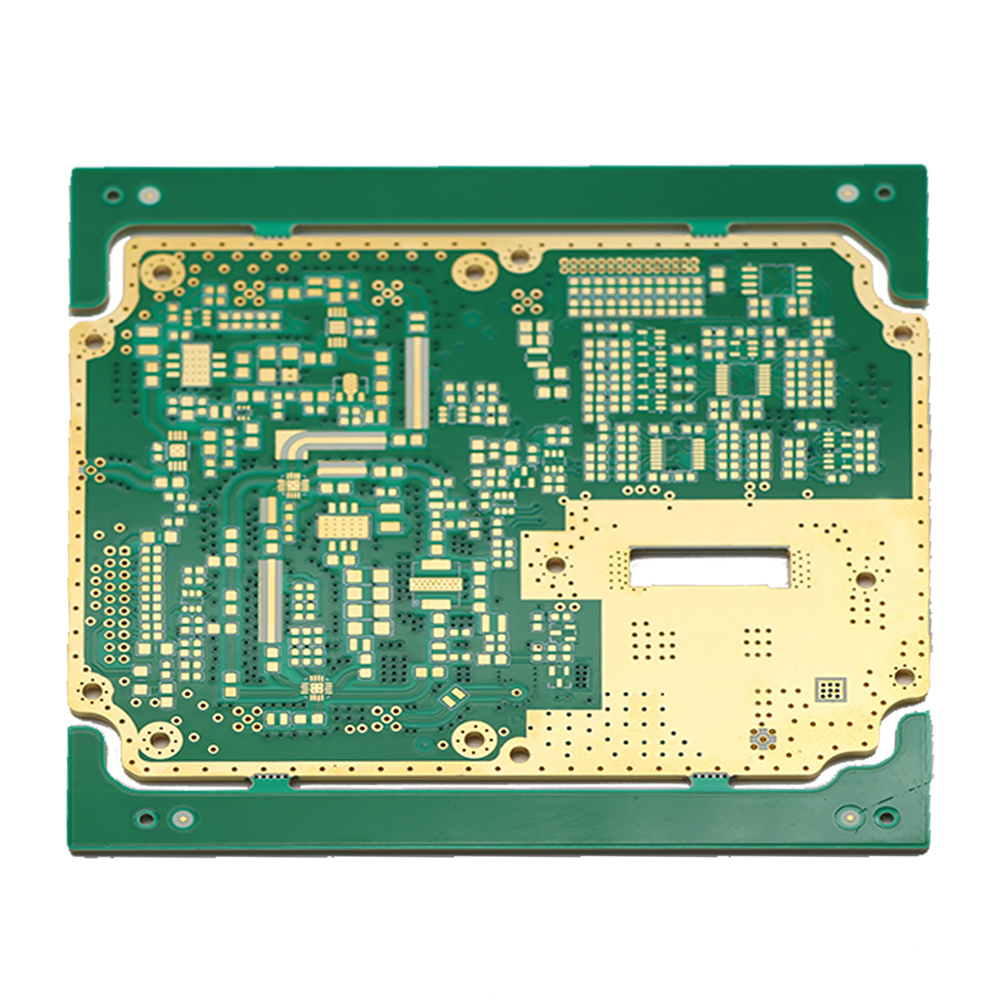

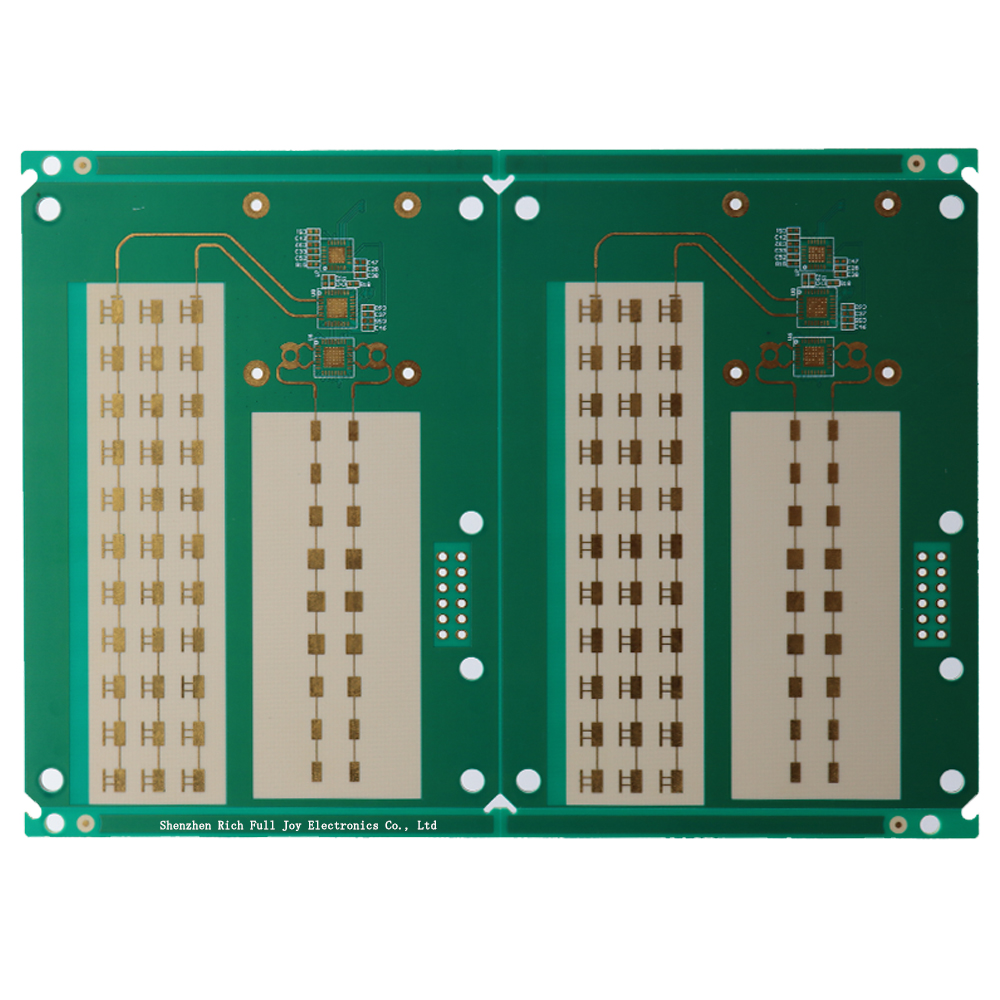

Rigid-flex board / 8 layer PCB for Bluetooth earphone

Classification of Rigid-Flex PCBs (see figure 1 for details)

A rigid-flex is a board that combines rigidity and flexibility, processing both the rigidity of rigid board and flexibility of flexible board.

Substrate: medium TG, high TG, low dielectric constant, low Df FR4, high-frequency material.

Substrate brands: Shengyi, Tenghui, Lianmao, Rogers, Panasonic, DuPont, Taihong.

Surface finish: HASL, HASL(Pb Free), ENIG, Immersion Tin, Immersion Silver, Gold Plating, OSP, ENIG+OSP, ENEPIG.

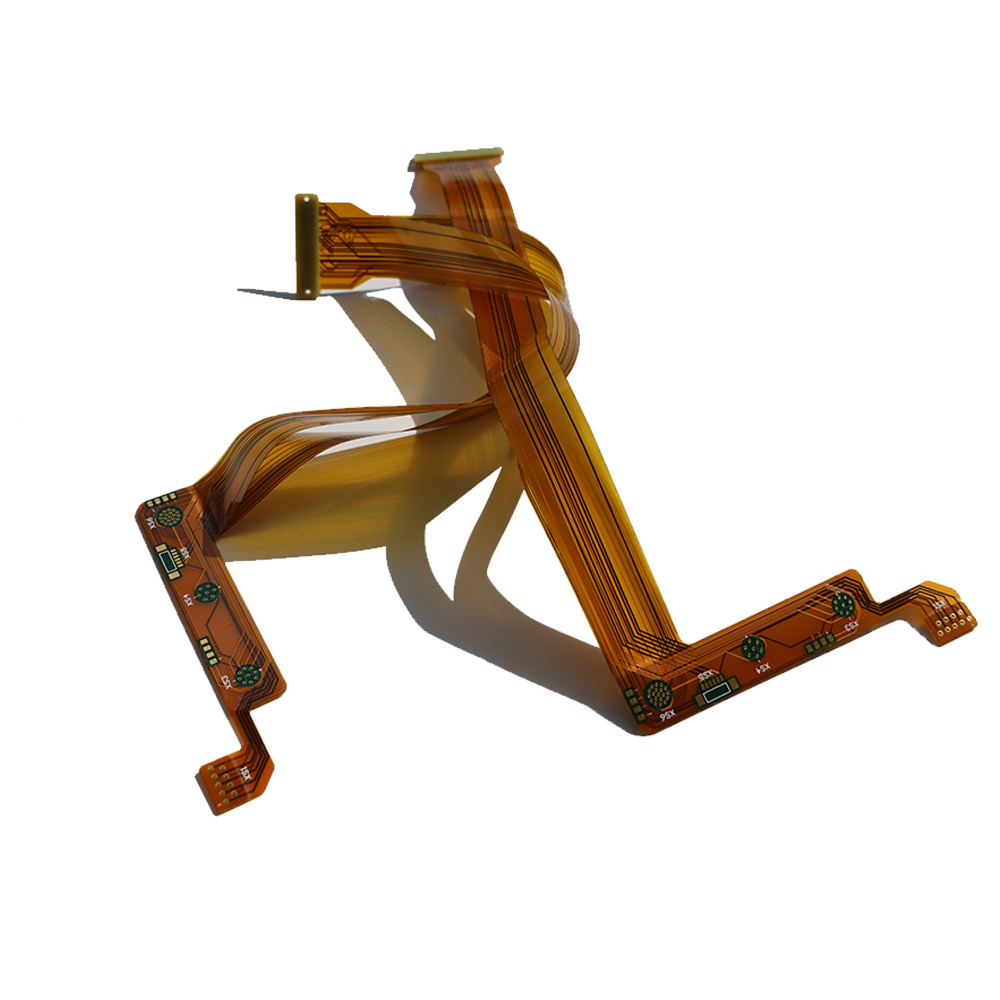

Rigid-Flex Board Au/Ni Type

b Gold plating can be divided into thin gold and thick gold according to thickness. Generally, gold below 4u”(0.41um) is called thin gold, while gold above 4u” is called thick gold. ENIG can only make thin gold, not thick gold. Only gold plating can make both thin and thick gold. The maximum thickness of thick gold on flexible board can be over 40u”. Thick gold is mainly used in working environments with bonding or wear resistance requirements.

b Gold plating can be divided into soft gold and hard gold by type. Soft gold is ordinary pure gold, while hard gold is cobalt containing gold. It’s precisely because cobalt is added that the hardness of the gold layer greatly increases exceeding 150HV to meet the wear resistance requirements.

Advantages of Rigid-Flex Board

Nowadays, design is increasingly pursuing miniaturization, low cost and high speed of products, especially in the mobile device market , which usually involves high-density electronic circuits. Using Rigid-Flex Boards will be an excellent choice for the peripheral devices connected through IO. Seven major advantages brought by the design requirements of integrating flexible board materials and rigid board materials in the manufacturing process, combining the 2 substrate materials with prepreg, and then achieving interlayer electrical connection of conductors through through-holes or blind/buried vias are as below :

a. 3D assembly to reduce circuits

b. Better connection reliability

c. Reduce the number of components and parts

d. Better impedance consistency

e. Can design highly complex stacking structure

f. Implement a more streamlined appearance design

g. Reduce size

Application

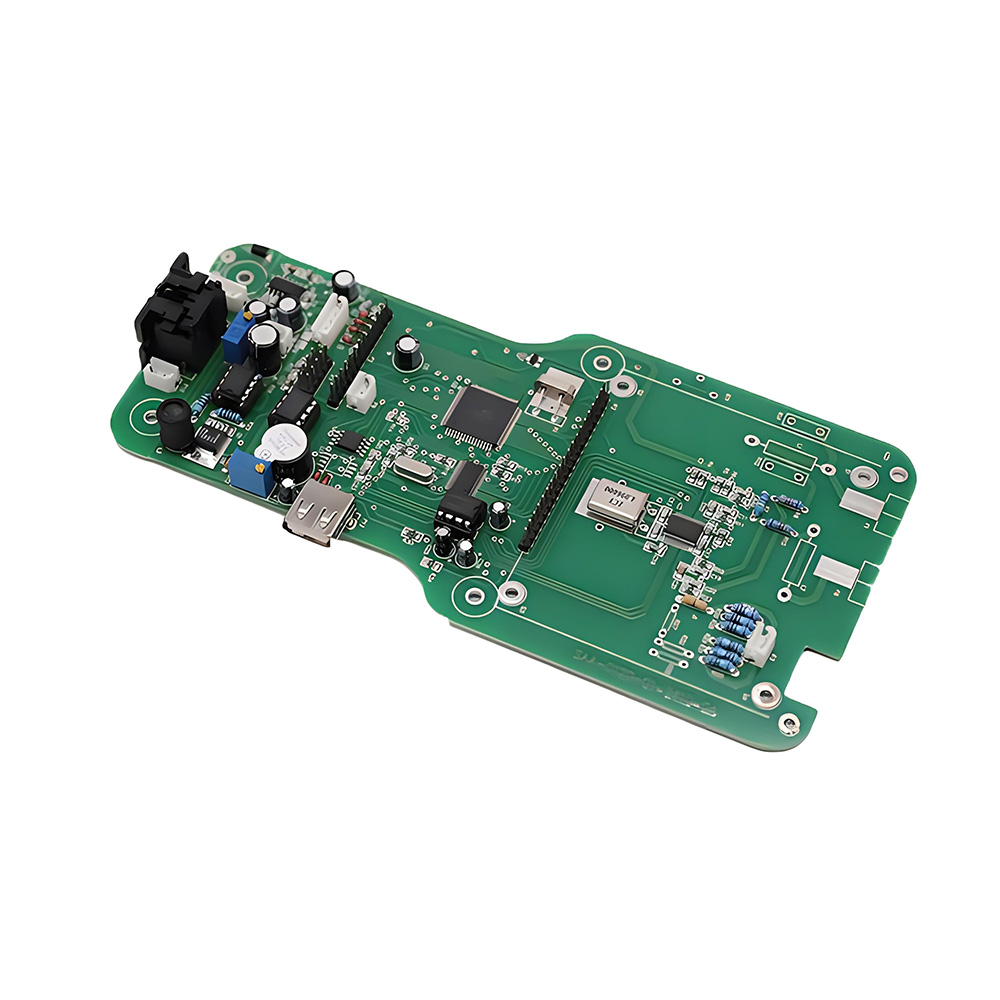

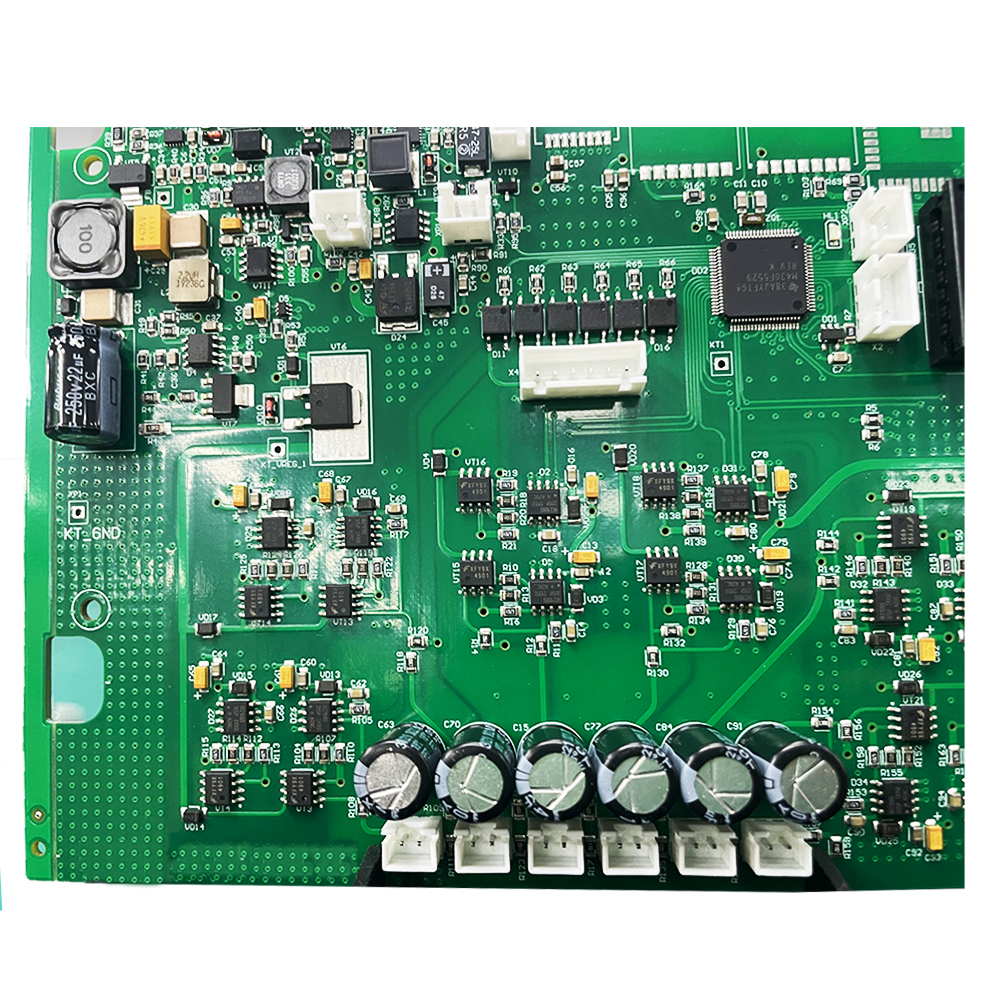

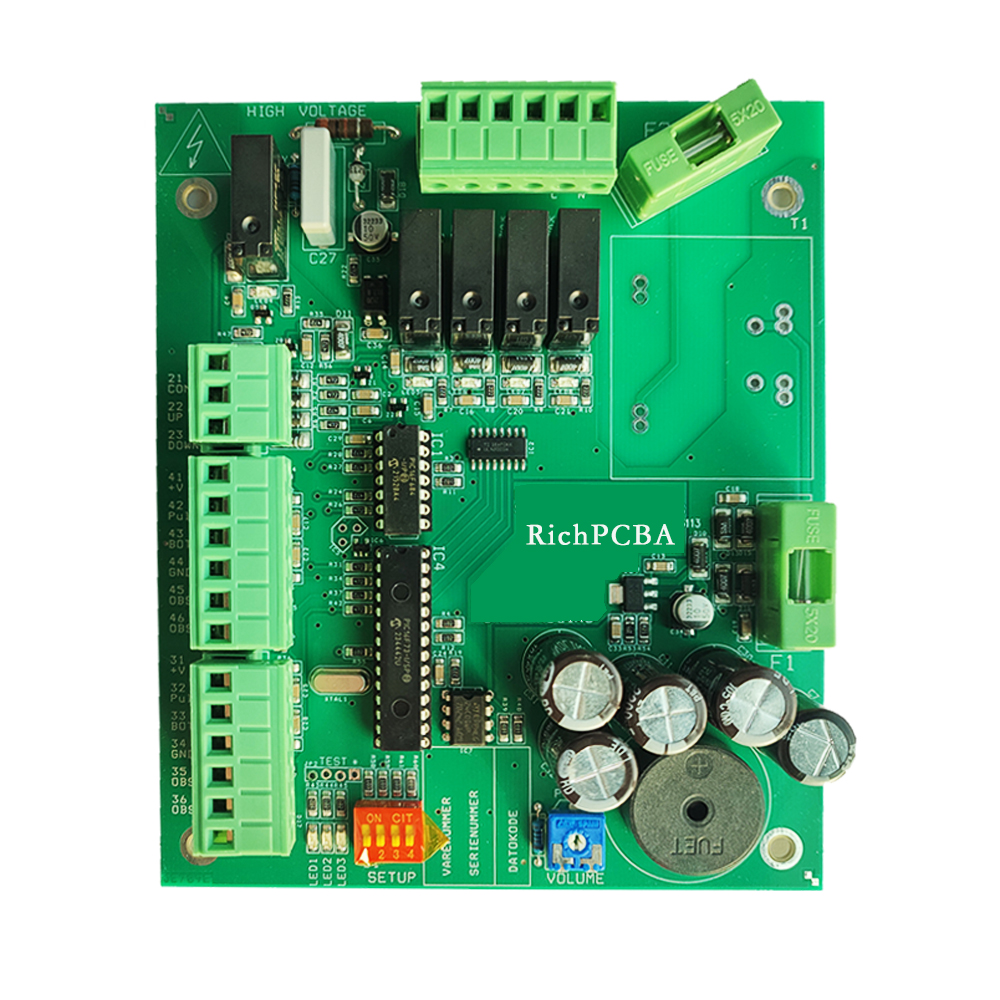

Rigid-Flex Board Application(see figure 3-1 for details)

Rigid-flex PCB is a composite board with the characteristics of both flexible circuit board and rigid circuit board, which is widely used in the fields as follow :

1. Electronics field: Rigid-flex PCBs are widely used in electronic products such as mobile phones, tablets, smart wearable devices, cameras, video recorders, calculators, drones and fitness monitors. In terms of performance, its rigid and flexible boards can connect different rigid PCBs and components in a three-dimensional manner. At the same circuit density, it can increase the total usage area of the PCB, improve its circuit carrying capacity, and reduce the signal transmission limit and assembly error rate of the contacts. Structurally speaking, the rigid-flex PCBs are lightweight and thin, allowing for flexible wiring, which is of substantial help in reducing volume and weight.

2. Automotive field: The rigid-flex PCBs are commonly used in automotive electronic systems, including buttons for connecting the motherboard to the steering wheel, connection between the vehicle's video system screen and control panel, operation connection of audio or function keys on side doors, reverse radar imaging system, sensors, vehicle communication system, satellite navigation, board for connecting the rear seat control panel and front-end controller, and external detection system.

3. Medical equipment field: The application of rigid-flex PCBs in medical equipment is becoming increasingly widespread, such as sign monitoring equipment, therapeutic instruments, imaging equipment, physiotherapy devices, cardiac pacemakers, endoscopes, ultrasound control devices, etc. Products in these fields require high reliability, high precision, low impedance loss, complete signal transmission quality, durability, etc. Due to the complexity of the manufacturing process and low output, the production cost is high.

4. Industrial control field: The rigid-flex PCBs are used in wide range of industrial applications including artificial satellites, radar systems, wireless communication, laser measurement and control instruments, sensors, nuclear magnetic analyzers, X-ray devices, infrared analyzers, etc.