PCB ASSEMBLY CAPABILITY

SMT, the full name is surface mount technology. SMT is a way to mount the components or parts onto the boards. Due to the better outcome and higher efficiency, SMT has become the primary approach used in the process of PCB assembly.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

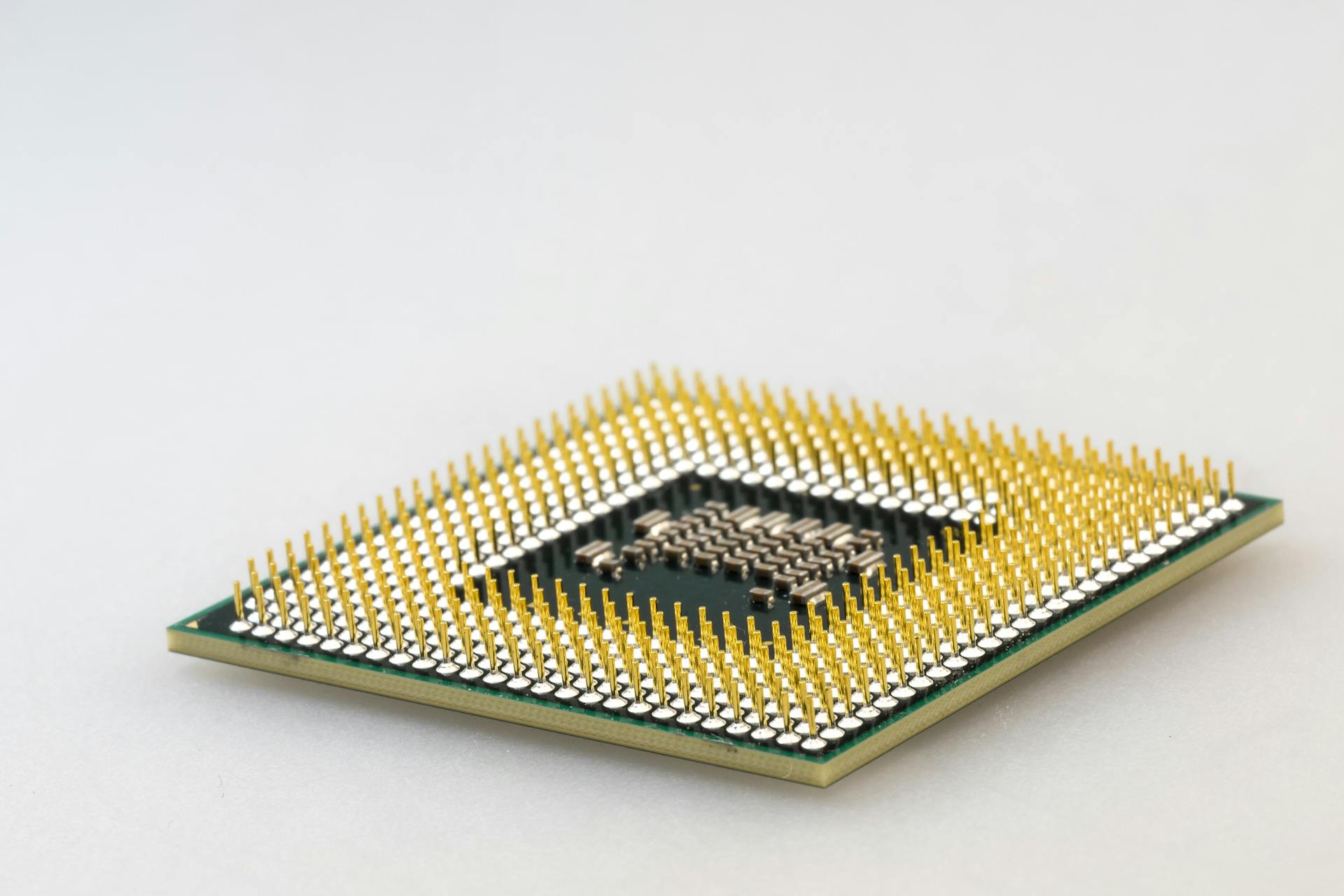

BGA ASSEMBLY CAPABILITY

BGA assembly refers to the process of mounting a Ball Grid Array (BGA) onto a PCB using the reflow soldering technique. BGA is a surface-mounted component that utilizes an array of solder balls for electrical interconnection. As the circuit board passes through a solder reflow oven, these solder balls melt, forming electrical connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more

black phosphating drywall screws

screws offer several advantages over other fastening methods. Unlike nails, screws provide a more secure and durable hold, as they create their own threading when being driven into a material.This threading ensures that the screw remains tightly in place, reducing the risk of loosening or disconnection over time. Furthermore. screws can be easily removed and replaced without causing damace to the material, making them a more practical option for temporary or adjustable connections.

read more