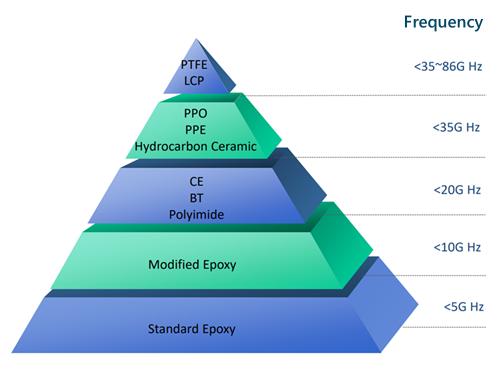

PCB Material Type

| High Speed & High Frequency Dk/Df grade of materials | ||

| Basis | Dk(1MHz) | Df(1MHz) |

| PTFE | 2 | 0.0004 |

| Hydrocarbon Ceramic | 2.2-2.6 | 0.001-0.005 |

| PPE | 2.5 | 0.001 |

| PPO | 2.45 | 0.0007 |

| CE | 2.7-3.0 | 0.003-0.005 |

| BT | 2.8-3.5 | 0.0015-0.003 |

| Polyimide | 3.2 | 0.004 |

| Epoxy | 3.6 | 0.025 |

| PCB MATERIAL TYPE | |||||

| Rogers | RO4350B、RO4450F、RO 4000serials、R04003C、92ML、RO3010RT6010LM、RO3003、RO4360G2、RT6002、RO3006、R04835TRO4350B、RO3035、Duroid® 5870 、duroid® 5880、ULTRALAM2000160021RO3003、RO3730、RO3850、RO4534、RO4730、RO4360series、RT、D6010Im、TMM10 | panasonic | Megtron2、M3、M4、 M4(R5725)、M4S、M6(series)、M7(series)、R-5675、R-5770、R-57721R-5775、R-57771R-57781R-5625、R-5720、R-5725、R1761、R1762、R1766 、R1755C、R1755V、R1755M、R-57751R5725、R1566、R1750C、R1752C、R1758C、R1757R1655V、R1566(W)、R1577(E)、R-1566、R1551、R1566、R1521、R1561、R1562、R1567、R1568、R1082、R1782、R1787、R-17811R1786、R5785、RF775、RF770 、RF705、R-F705T、RO1200 | Taiflex | 05151052010525、1025、1035、2FCCL(series)、3FCCL(series)、BT (series) |

| Isola | 370HR、PCL-FR-370HR、PCL-FR-370 TurbO、PCL-HP-850、PCLFR-250HR、PCL-HP-870、1S400、FR-254、Aut0-HR PCL-HP-850)PCL-FR-250HR、PCL-HP-870、185HR、FR408HR、FR408、IS811 、IS415、1-SpeediGigaSync Stratus ML200+、FR406、FR406N、FR406BC、FR4021185HR、IS410、DSDE104i-3、IS620、1S6801IS680AG-300、I-TERA MT、IS680-330、1S680-345、Tachyon-100G | SYTECH | S1141、 S0401(140℃) 、S1000H、S1000HB(150℃)、S1000-2、 S1000-2B(170℃ )、S1600、S1145(series)、S1125、S7542、S1150(series)、S1170(series)、S1190、S7439、S7135、S7136、S7038、S7045(series)、S1150G(series170℃) 、S31101S3116、S75421S2600、S1165、S1155(K)、S1130、SF302、S305、SAR15、SAR20、SH260、ST210G、S1140(series)、S7335、S7338(170℃)、S7040G(170℃)、Synamic 6(N) | 3M | 9460、9077、9458、468、090、779、458 |

| ITEQ |

IT158TC、IT150GS(150℃)、IT-158TC/IT-158BS(150℃)、IT-180ATC/IT-180ABS(175℃) 、IT180I/IT180IBS(170℃)IT140TC、IT180TC、IT170GRA1/IT-170GRA1BS(170℃)、IT150DA/IT150DABS(180℃)、IT200LKTC、IT958G(170℃) 、IT968/IT968BS(170℃) 、IT968TC、IT968SE、IT140GTC、IT150GTC、IT150GL1TC、IT150GSTC、FD131218NFB1、FS252035NFB1、IT-859GTA、IT170GRA1、IT150DA、IT-200LK/IT200LKBS(200℃)、IT968 |

TuC |

TU-752、TU-768F、TU-768/ TU-768P(180℃)TU-788、TU-668(series)、TU-862(series)、TU862 HF/ TU86P HF(170℃)、TU-862(series)、TU-862S、TU-863+ (170℃)、TU-742HF、TU-742MV、TU-747P HF (150℃)、TU747LK(150℃)、TU-865、TU-868、TU-815、TU722、TU-662/ TU-66P(150℃)、TU-668/TU-668P(150℃)、TTU721、TU622-5、TU622-LE、TU-872SLK (190℃) TU-872SLKSP (190℃)、TU933、TU933/TU933+(200℃)、TU930、TU832、TU883(series)、TU803、TU865 |

Laird |

T-lam HTD04、HTD06、1KA 04、1KA 06、1KA 08 、HTD03、 LLD 、ASTM6061 |

| Taconic |

RF-35(series)、TLY-5、TLY-5A、TLY(series)、TLP-5、TLX-(series)、TLF35、TLC-32、TRF-43、TLX(series)、RF30(series))、RF60A、TLF-34 、TSM-DS3、TLC-30、RF-35、RF-35A2、TLC-35、RF-60A、RF-60TCCER-10、EZI0 |

Dupont |

AP7163E、AP7164E、AP8515R、AP9111R、AP9212R、AP7156EAP7125E、AP8525、AP9121R、AP9222R、AP8535R 、AP9131R、AP9232R 、AP8545R、AP9141R、AP9242R、AP8555R、AP9151R、AP9252R、AP8565R、AP9161R、AP9262R、FR(Series) |

Bergquist | MP-06503、HT-7006、HT-04503、HT-09009、CML-11006、HPL -03015 |

| Arlon |

33N135N185N、AD250、TC350、CLTE-AT、25FR、AD270、AD300、AD300C、AD320、AD350、AD350A、25N、AD255(C)(A)、AD250(A)、 DiClad527 、DiClad880 、CLTE-XT、CLTE-AT、 CLTE !TC600 、AD600 、AD1000 |

Ventec | VT-47(series)、VT-481(series)、VT42(series)、VT-47RD、VT-5751VT-585、VT-47TC、VT-47PP、VT-41、VT-41RD、VT-45、VT-441、VT-447、VT-45RD、VT-4Aseries、VT-4B series、VT-901 |

Kingboard |

KB6160、KB6164、KB6165、KB6167、KB6165F、KB6150、KB5150、KB6060、KB6064 HF-140PP、KB-6160C、KB1150、KB7150 |

| Nanya | NP-140TL/NP-140B (135℃) NP-140OR/NP-140B (135℃) NP-150 TL/NP-150B(150℃)、NPG-TL/NPG-B(150℃)、NPG-150N(150℃) NP-170R(TL、SR、STL、NP、170℃)、NPG171(170℃)、175FR(FTL、FMTL、170℃)、NP-180TL/NP-180B(175℃)、NY2150、NY2170、NA6200、NY2140、NY1140 |

Nelco | N4100(series)、N4000(series)1N4103(series)、N4203(series)、N4105(series)、N4805(series)、N7000(series)、N9000(series)、N4350、N4380、NP-140(series)、NY9217、NH9300、NX9300、N9350-13RF、N9320-13RF、MW4000、MW3000、MW2000、MW1000、N4000-13、EP、SIN4800-20、SI | Chin-Shi |

CS-AL-88(series)、CS-AL-89(series)、AD2(2W)、AD3(3W)、AD5(5W)、AD8(8W)、 M9(9W) |

| ThinFlex | A-2010RD(series)、A-1010RD(series)、G-1010RD(series)、X-1005RS(series)、G6-0610ED、1.1010RS(series)、P-1005ED、J-1010RS(series)、K-1010RS(series)、T-1010RS(series)、TinFex-KB(Adhesive sheet)、 TinFlex-N(Adhesive sheet)、ThinFlex-R(Adhesive sheet)、ThinFlex-U(Adhesive sheet)、ThinFlexKC( Bonding Sheet)、 FhinFlex-l(Coverlay series)、 FhinFlex-M(Q、V、KA) | EMC | EM-220、 EM-22B(135℃) 、EM285、EM285B(150℃)、 EM370(150℃)EM280、EM28B(170℃)、EM825(series)、EM828G/EM828BG(170℃)、MEG4/R5620(170℃)、 MEGM/R5630(170℃)、 EM-827 EM-827B(170℃) 、 MEG6/R5670(170℃)、EM888、EM888B(190℃) MEG7/R5680(200℃)、EM526(220℃)、EM528 (220℃)、EM891、EM220、EM37、EM320、EM310、EM-355(D) | Stiffener | steel sheet, leaf spring, FR4, adhesive backing |

| Classification | Substrate's Type | Category (delivery area of commonly used substrates<10㎡) | Substrate's Application Fields |

| Regular Substrates | Regular TG FR4: | S1141、TU-662、KB-6160、IT-158(middle TG)、VT-42、VT-42S、NP-155F(TG155) | refrigerator, beverage dispenser, air conditioner, electric fan, ventitation fan, hot and cold air generator, air dihumidifier |

| Regular Substrates | High TG FR4: | S1000-2、S1000-2M、IT180A、TU-768、NP-175F、370HR | washing machine, dryer, electric iron, vacuum cleaner, floor waxing machine |

| Regular Substrates | High TG, halogen free: | S1170G、KB-6167G、NPG-170D、IT170G | electrothermal blanket, electrothermal quilt, electrothermal suit, air heater, electric shaver, hair dryer, hair straightener, ultrasonic facial cleanser, electric massager, air negative ion generator |

| Regular Substrates | Middle TG, halogen free: | S1150G、KB-6165G、NPG-150、IT150GSTC | TV, radio, recorder, Video player, camera, combinated sound system, fireworks alarm, electric bell |

| Regular Substrates | Halogen free, high CTI: | S1151G(CTI≥600V) | machinery manufacturing industry, electronic communication equipment manufacturing industry, automobile manufacturing industry, shipbuilding industry |

| Regular Substrates | High CTI(CTI≥600V): | S1600、KB-6160C | Computer, peripheral device, communication equipment, instrument & meter, office automation equipment |

| Regular Substrates | High TG(TG>250℃) | SH260(TG 250°,dk4.12-4.22) VT901(TG 250°, DK3.9-4.2, halogen free) | Aerospace, underground drilling, long-term high & low temperatures, aging boards, etc. |

| Regular Substrates | Low CTI | SI10U(S)、SI643HU、HL832NX、DS-7049HGB | chip, packaging substrate |

| Regular Substrates | Ceramic powder filled high-frequency board: | Rogers4 series such as RO4003C、RO4350B,etc.、Arlon25N、S7136、S7135 、WL-CT350 | satellite TV LNB, microstrip line, power amplifier |

| Regular Substrates | PTFE high-frequency material: | Rogers5 seires, Taconic series, Arlon series, Taizhou Wangling F4B series | high frequency microwave, radio frequency |

| Regular Substrates | PP for high-frequency substrate: | RO4450F、RO4450T、RO3010、RO3003、RO3006、Synamic6、FSD206PP | radio communication, broadcasting, television, radar, navigation, electronic countermeasures, remote sensing, radio astronomy |

| High-speed Series | Standard Loss(<5G Hz) | EM370D、Tu-862、S7038、S1165、Isola-FR408HR、Isola-FR406、EM370 、EM828G IT170GRA NP175FM、TU662、IT158、FR-370HR、IT180、EM827、NP175FM、EM825 | 2G, products with high-speed data signal transmission, sucha as 5G and servers |

| High-speed Series | Middle loss(<10G Hz) | FR408、TU-872LK、TU-872SLK、TU-872SLK SP、M4(R5725)、NPG-170D、EM-526、 TU-863+、MEG4、N4000-13、Synamic4、EM-888 、I-Speed(Isola) N4800-20SI(Nelco) IT-958G、IT170GA1TC、NPG1、NPG170D、Megtron4、IT200LK、IT958G、 | 3G high-speed server, network and telecom applications |

| High-speed Series | Low loss(≥20G Hz) | TU-883C、TU-883(T2)、TU-883SP、IT-968G、EM-528、EM-528K、M6(R5775)、Megtron6、M6(G)、M6(N)、EM-891、EM-891K、EM888K、 I-Tera、 RO4350、 IT968(SE) NPG186、kappa 438、Meteorwave1000、2000、3000 | 4G, 5G, laptop, server, network device, peripherals, chip, electronic component, car key |

| High-speed Series | Very low los(≥20G Hz) | IT-988G、TU-933(T3)、TU-883A SP、TU-933+、M7(R5785)、M7(N)、IT-988G SE、EM-891K、EM-890、Tachyon-100G、EM-890K、 RO3003 ASTRA MT77、MEG7、Tu-933、Meteorwave4000(Nelco)、IT-988、Tachyon 100G(Isola)、Megtron7(N)、 | 5G, communication device manufacturing, wireless communication device, satellite communication device manufacturing, CPU, processer |

| High-speed Series | Ultra low loss(≥25G Hz) | ASTRA MT77/R-5515/HN30X/mmwave77/RO3003 | 5G, mobile broadband(eMBB), large-scale IoT, autonomous driving, internet system, navigation system, optical module, optical communication products |

| High-frequency seires | High frequency series (DK : 2.2-2.25) | RT5880、RT5880LZ(dk2.0) TLY-5(Taconic) SCGA-500 GF220(SYST)、F4BK225、F4BTMS220 、FSD217、DiClad880,5880 | wireless link, transmitter, powder divider, combiner, filter, base station antenna, millimeter wave radar |

| High-frequency seires | High frequency series (DK : 2.33) | TLY-3(Taconic)、RT5870、DiClad870、FSD233G | stripline & microstrip line circuits, satellite communication, automotive radar, wave filter, coupler, avionics, phased array antenna, base station |

| High-frequency seires | High frequency series (DK : 2.45) | TLX-0(Taconic)、 TLX-8(Taconic)、DiClad527、FSD245G | radar system, phased array antenna, mobile communication system, microwave testing equipment, microwave transmission device and RF components |

| High-frequency seires | High frequency series (DK : 2.5-2.55) | AD250(Arlon)、TLT-9(Taconic)、TLY-9(Taconic)、 SCGA-500 GF255(SYST)、TLT-8(Taconic)、TLY-8(Taconic)、F4BM255、FSD255G、FSD825T、RO4725 | antenna, base station, 5G |

| High-frequency seires | High frequency series (DK : 2.6-2.65) | TLT-7(Taconic)、TLY-7(Taconic)、TLT-6(Taconic)、TLY-6(Taconic)、SCGA-500 GF265(SYST)、F4BM265、、F4BTMS265/AD265A/AD260A/FSD265G/FSD260G | base station antenna, satellite communication, wave filter, coupler, low-noise amplifier, power amplifier, phased array antenna, avionics and aerospace |

| High-frequency seires | High frequency series (DK : 2.7-2.75) | AD270(Arlon)、TLC-27(Taconic) | antenna, RF, high-speed digital circuit board |

| High-frequency seires | High frequency series (DK : 2.92-2.94) | RO6002、CLTE(Arlon)、F4BTM、S294、FSD300N | aerospace equipment, microwave, RF, radar, feed network, phase sensitive antenna, phased array antenna, satellite communication |

| High-frequency seires | High frequency series (DK : 2.95) | AD295(Arlon)、TLE-95(Taconic) | microwave radio, satellite antenna system, passive components |

| High-frequency seires | High frequency series (DK : 2.97-2.98) | AD300C PTFE ceramic、FSD300NA、RF-30 | base station antenna, power amplifier |

| High-frequency seires | High frequency series (DK : 3.0) | SCGA GF300、AR-320、CLTE-AT(Arlon)、TSM-30(Taconic)、TLC-30(Taconic)、F4BK300、ZYF300CA;RO4730G、RO3003C、RO3730、RO3203(Rogers)R03003/RT6002/CLTE-AT/RO4730JXR/RO4730G3/RO4450C/RO2929/FR28/FSD300、FSD886T/RF-30A | communication satellite, back board, base station antenna, satellite transmission antenna, automotive radar, sensor, wireless link, transmitter, power divider, combiner, filter |

| High-frequency seires | High frequency series (DK : 3.2-3.28) | AD320(Arlon)、AR-320(Arlon)、TLC-32(Taconic)、TMM-3(Rogers) 、25N(Arlon)、SYSTLNB33、FSD320N | transmitter, receiver, antenna, carrier wave telephone terminal |

| High-frequency seires | High frequency series (DK : 3.37-3.40) | 25FR(Arlon)、Ro4003C、WL-CT338、RO4533、N4103-13SI、N4103-13EPSI( Neclo)、25N | automotive, aviation, defense, communication infrastructure, semi-conductor, high-speed data |

| High-frequency seires | High frequency series (DK : 3.45-3.5) | RO4350B、RO4835、AR-350(Arlon)、RF-35(Taconic)、F4BK350 、 WL-CT350、S7136、S7135、IS680-345ISOLA 、RO4350B、FL700LD(SYST)、FX-2、MCL-LX-67(MCL-LX-67)、TC350(ARLON)、RF35A2、RF35(TACONIC)、R04003、FSD883、FSD350、FSD888 | satellite TV LNB, microstrip line, power amplifier, filter, connector, wireless link, transmitter, power divider, combiner, base station antenna |

| High-frequency seires | High frequency series (DK : 3.60-3.70) | AD360(Arlon)、IT150DA(ITEQ)、M6 (R5775K)Panasonic 、FR408HR(ISOLA)、FL700(SYST)、N4103-13、N4103-13EP、Mercurywave 9350(NECLO)、EM828(EMC)、Multiclad(ARLON)、SY7136、FSD360N | automotive, defense, communication infrastructure, semiconductor, high-speed data, back board, power amplifier, receiver |

| High-frequency seires | High frequency series (DK : 3.77) | FR408(ISOLA) | automotive, aviation, defense, communication infrastructure, semiconductor, high-speed data, network equipment, measurement instrument |

| High-frequency seires | High frequency series (DK : 3.8) | S7439(EL230T)SYST、IT200LK( ITEQ)、M4 (R5725)(Panasonic)、TU-872/SLK(TUC) | network device, measurement equipment, router, server, exchanger, high-performance computer, back board for base station, daughter board |

| High-frequency seires | High frequency series (DK : 3.9) | S7240(SYST) | backboard, server, router |

| High-frequency seires | High frequency series (DK : 4.3) | EL190T (SYST) | internet router, server, semiconductor testing device, on-board substrate |

| High-frequency seires | High frequency series (DK : 4.5) | AR-450(Arlon)、TMM-4(Rogers)、FSD450 | stripline, microstrip line |

| High-frequency seires | High frequency series (DK : 6.0) | AR-600(Arlon)、TMM-6(Rogers) | wireless infrastructure, power amplifier, radar system, high-speed digital system, hybrid vehicle, high-voltage rail transit traction, laser system |

| High-frequency seires | High frequency series (DK : 6.15) | RO3006、RO6006、RO4360、Taconic RF-60A、R03006/AD600L、RO4360G2 TMM6、AD600L/TMM6、FSD615T | wave filter, coupler |

| High-frequency seires | High frequency series (DK : 9.2-9.8) | TMM-10(Rogers DK9.2)、TMM-10i(Rogers DK9.8)、FSD960NT | RF & microwave circuit, GPS antenna, power amplifier & combiner, microstrip antenna,dielectric polarizer & lense, chip testing, Beidou satellites |

| High-frequency seires | High frequency series (DK : 10.0-10.2) | AR-1000(Arlon)、CER-10(Taconic)、RO3010(dk11.2)、RO3210(dk11.2)、RT6010、TF—1/2、TMM10、AD1000、FSD1020GR、FSD1000T、SF1020NT | millimeter wave radar, aerospace, 5G, Beidou satellites |