about usWELCOME TO LEARN ABOUT OUR ENTERPRISE

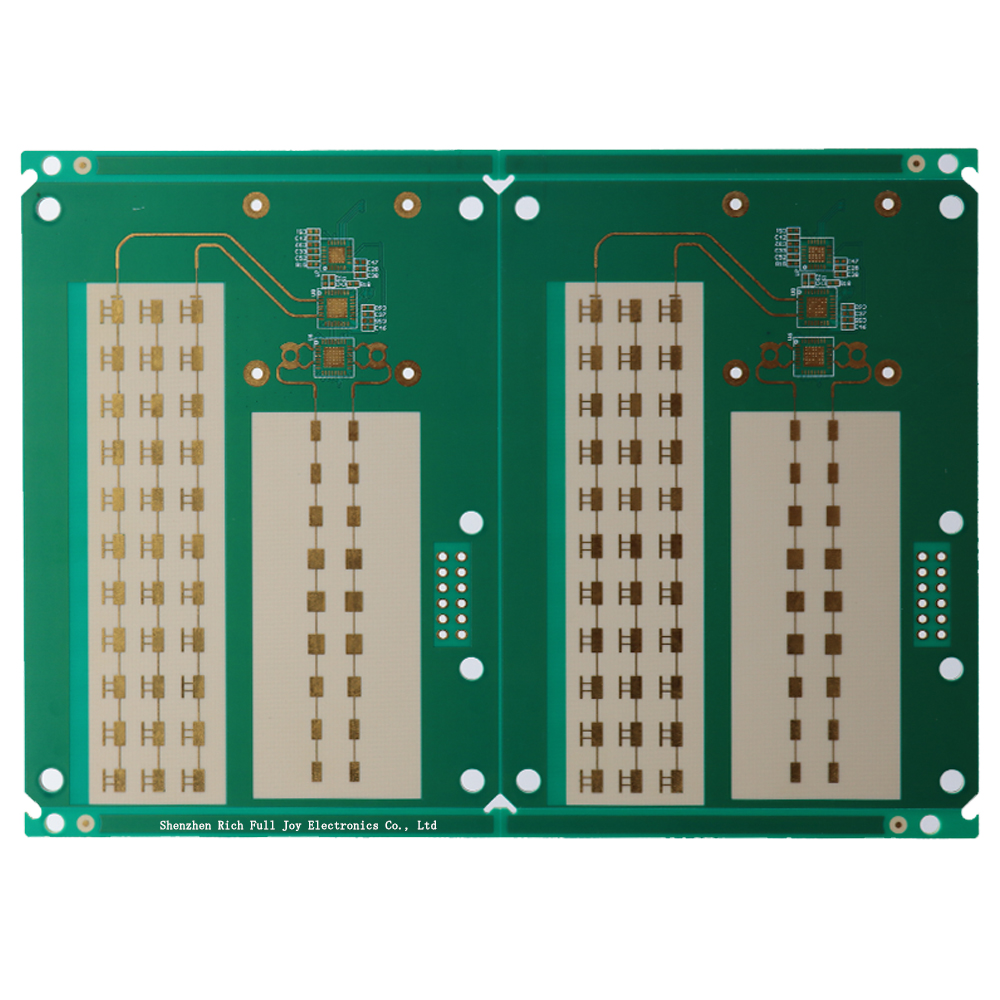

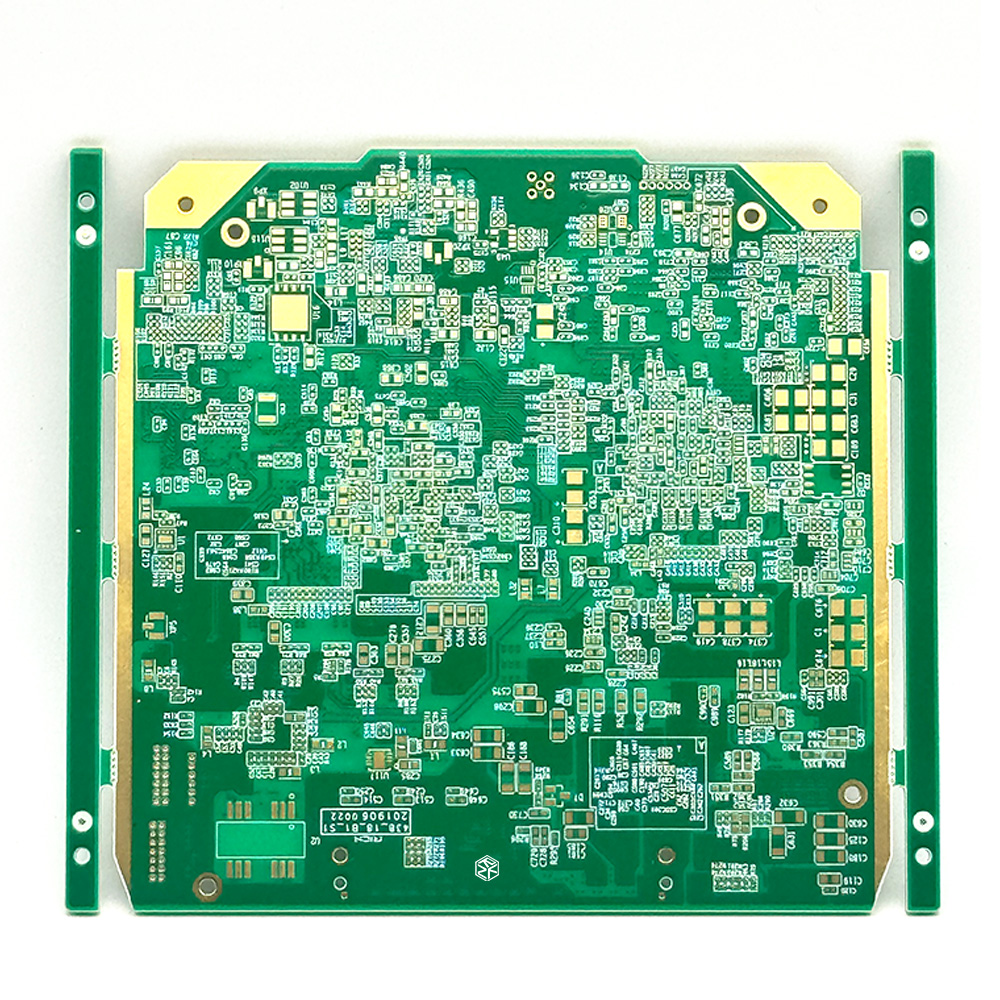

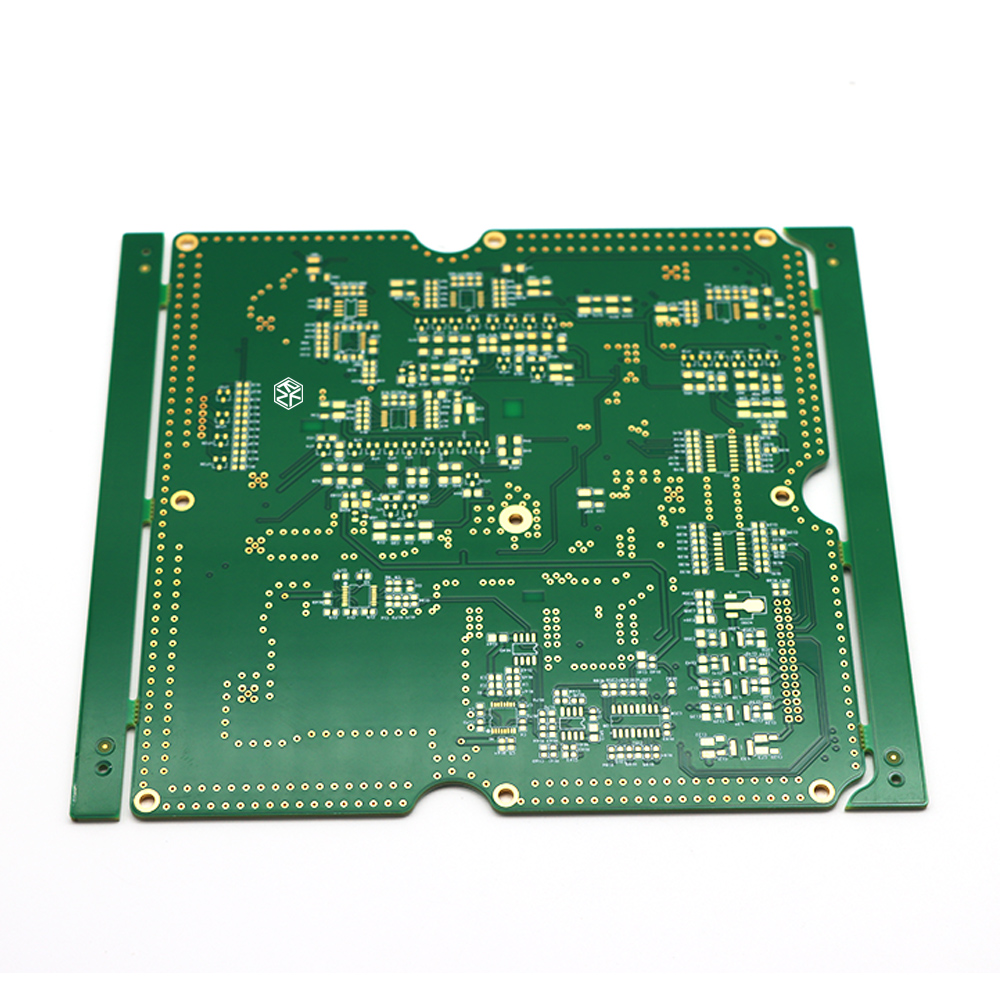

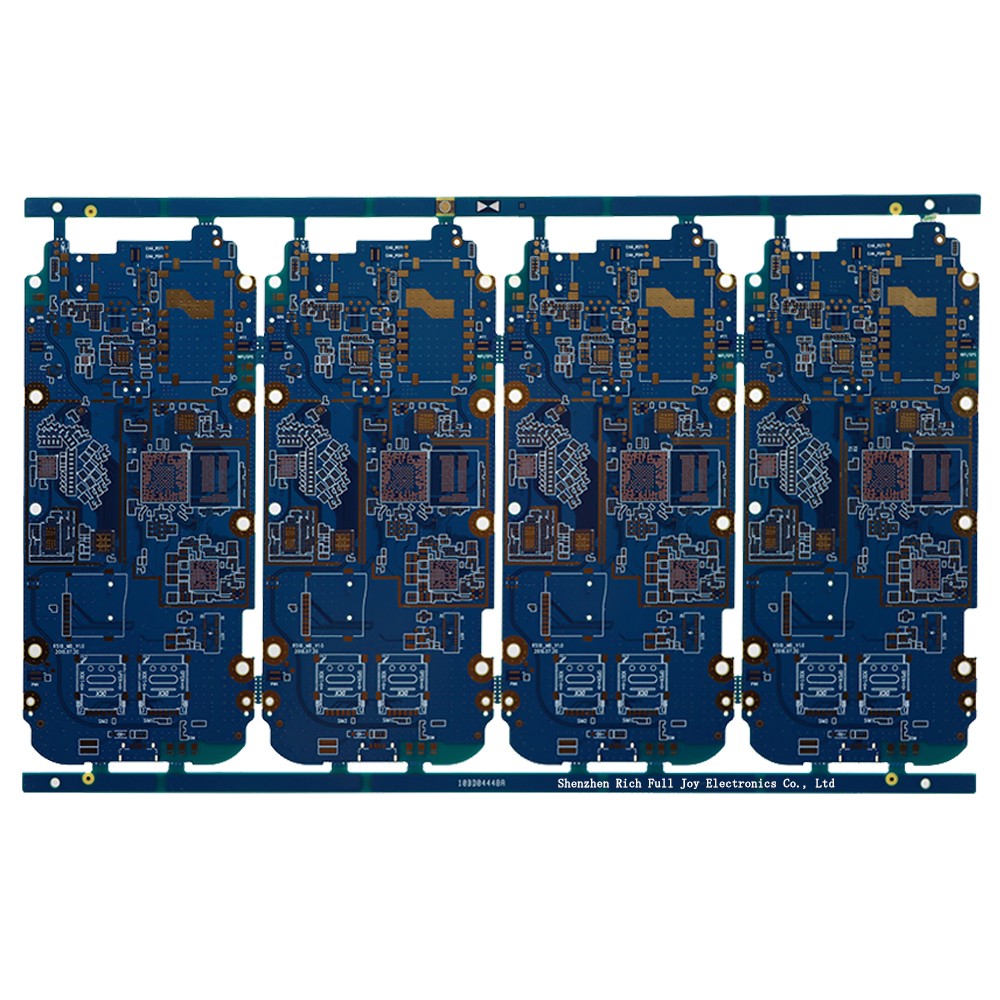

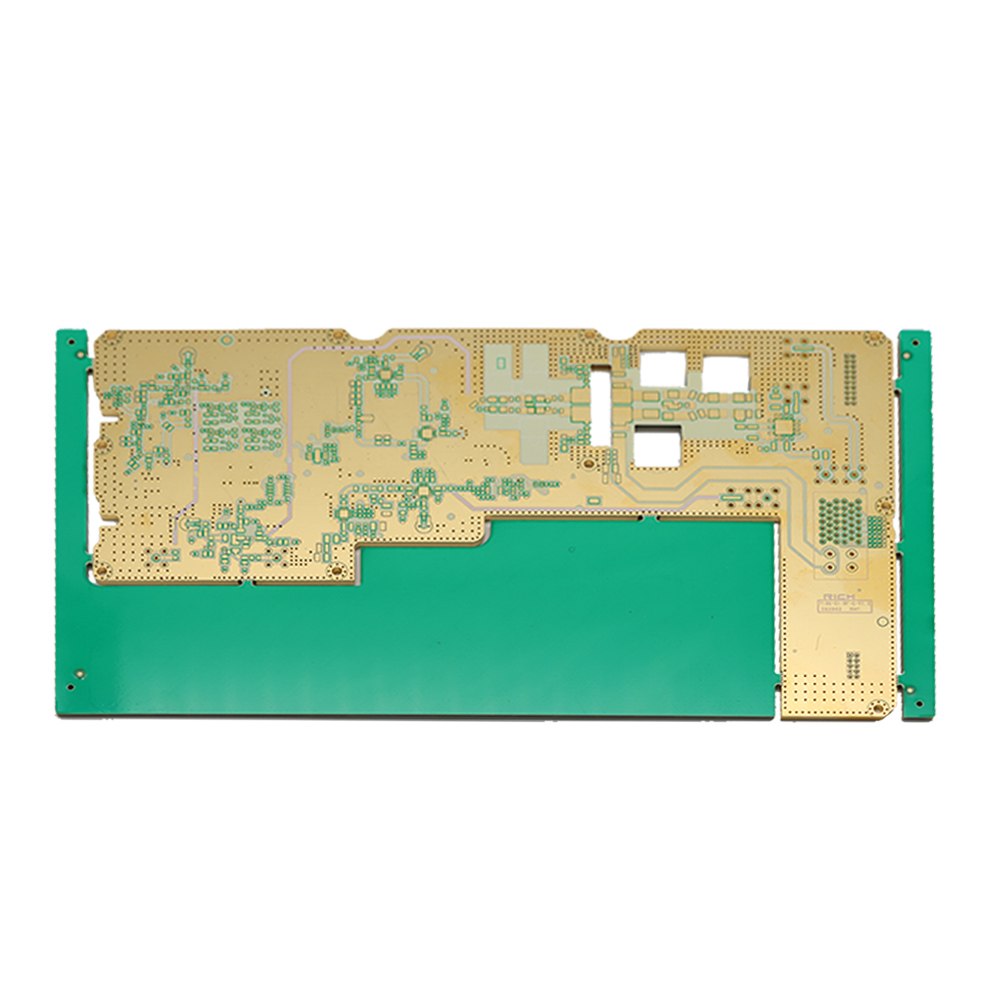

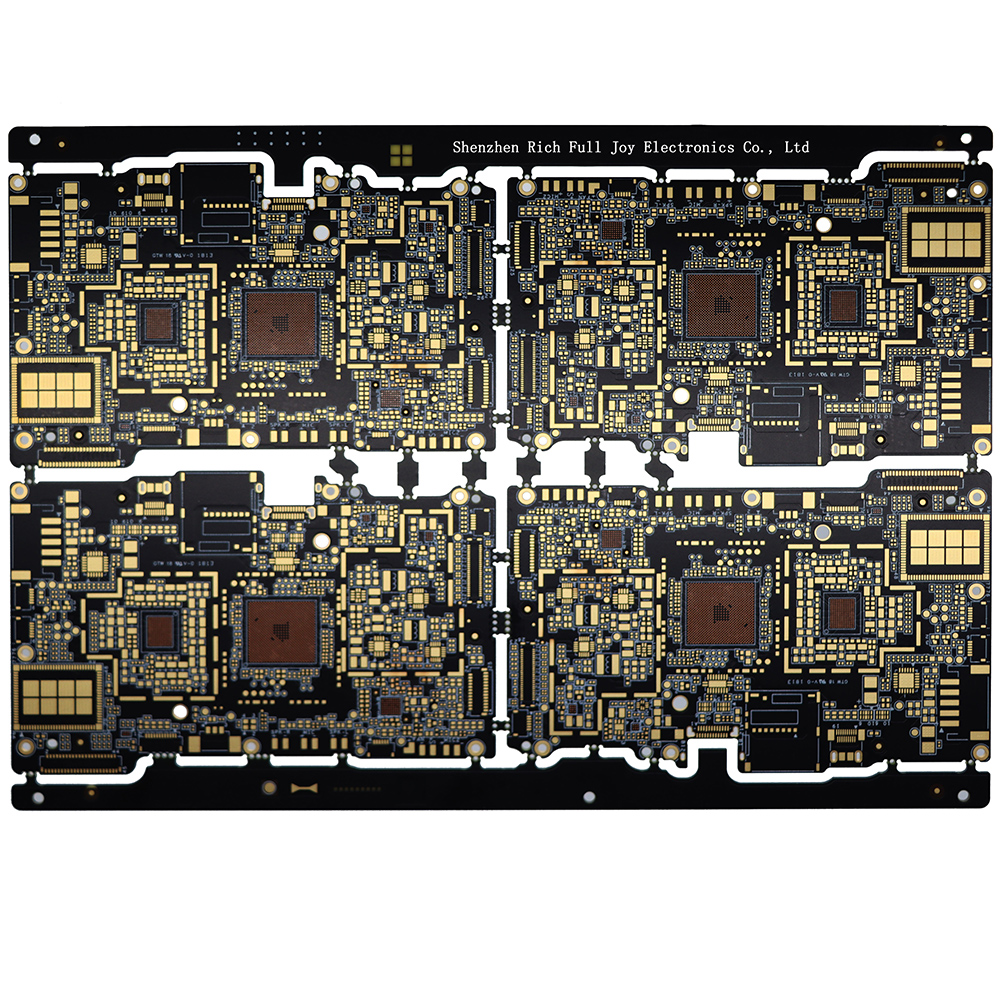

Shenzhen Rich Full Joy Electronics Co., Ltd.

-

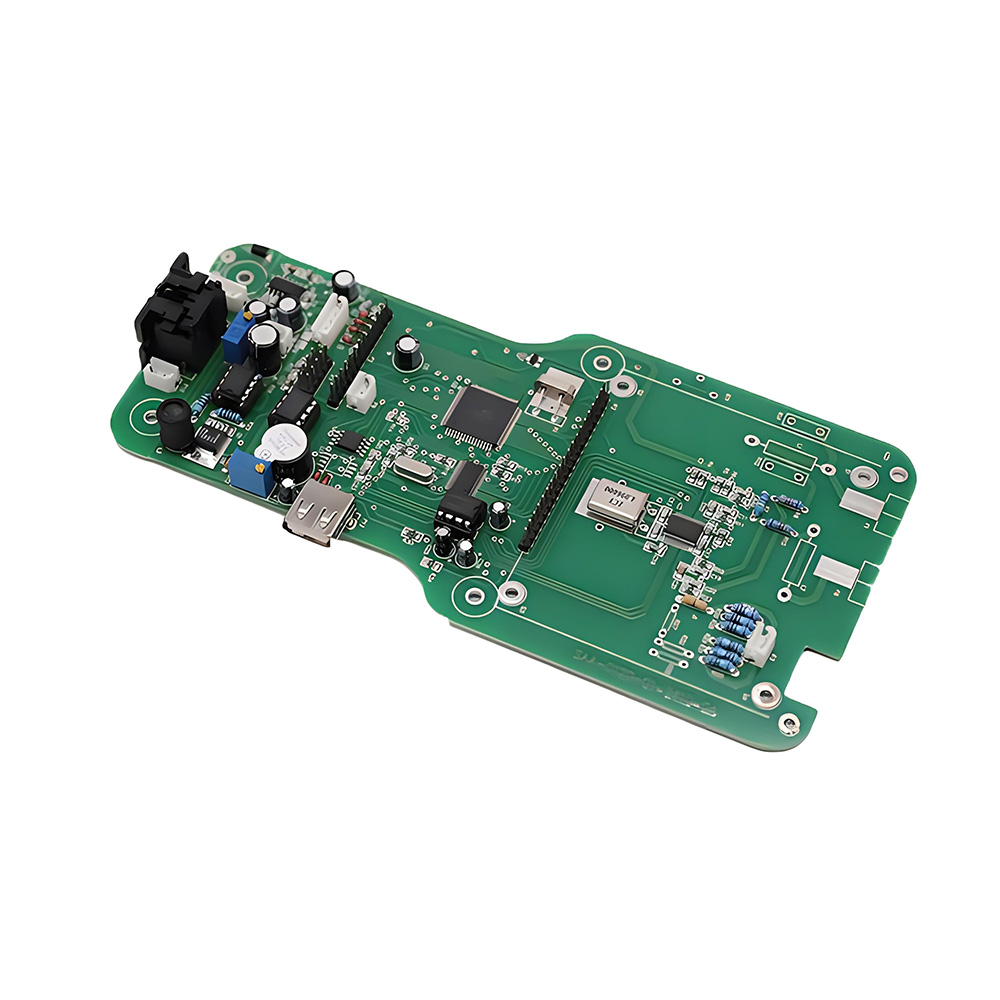

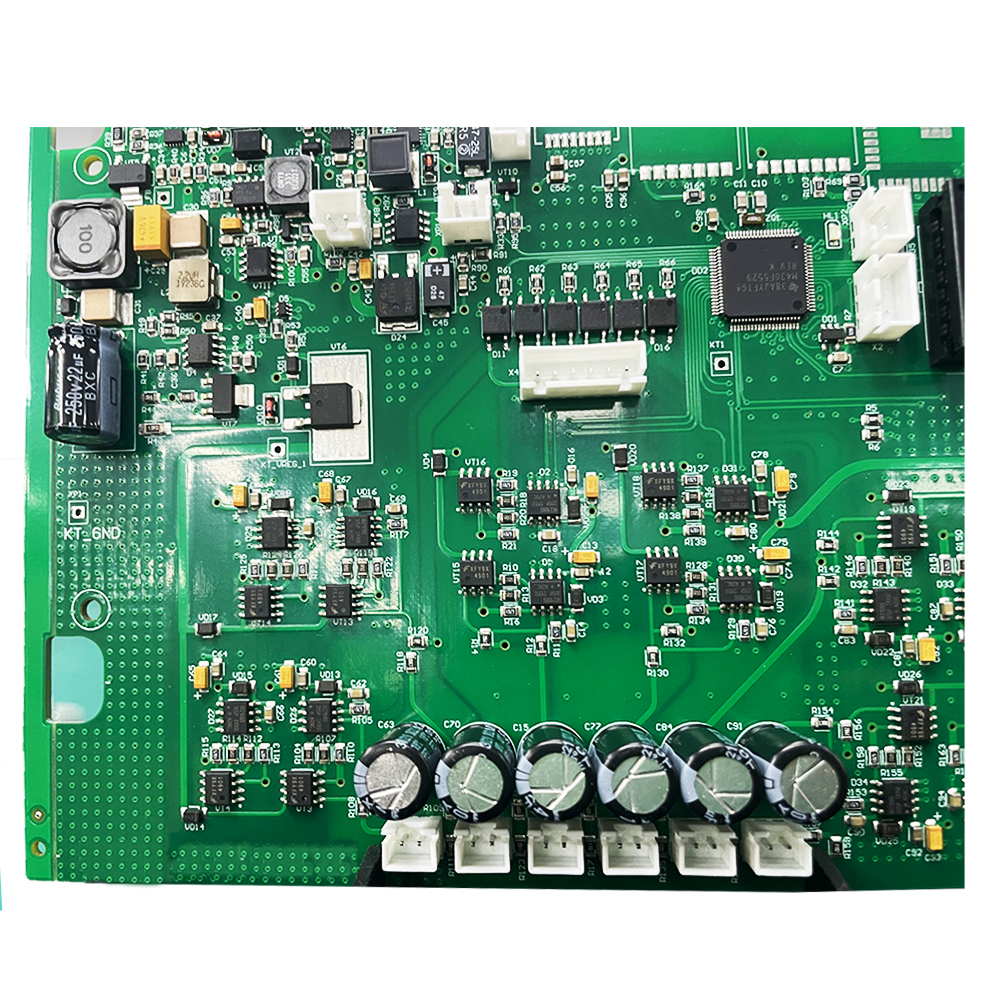

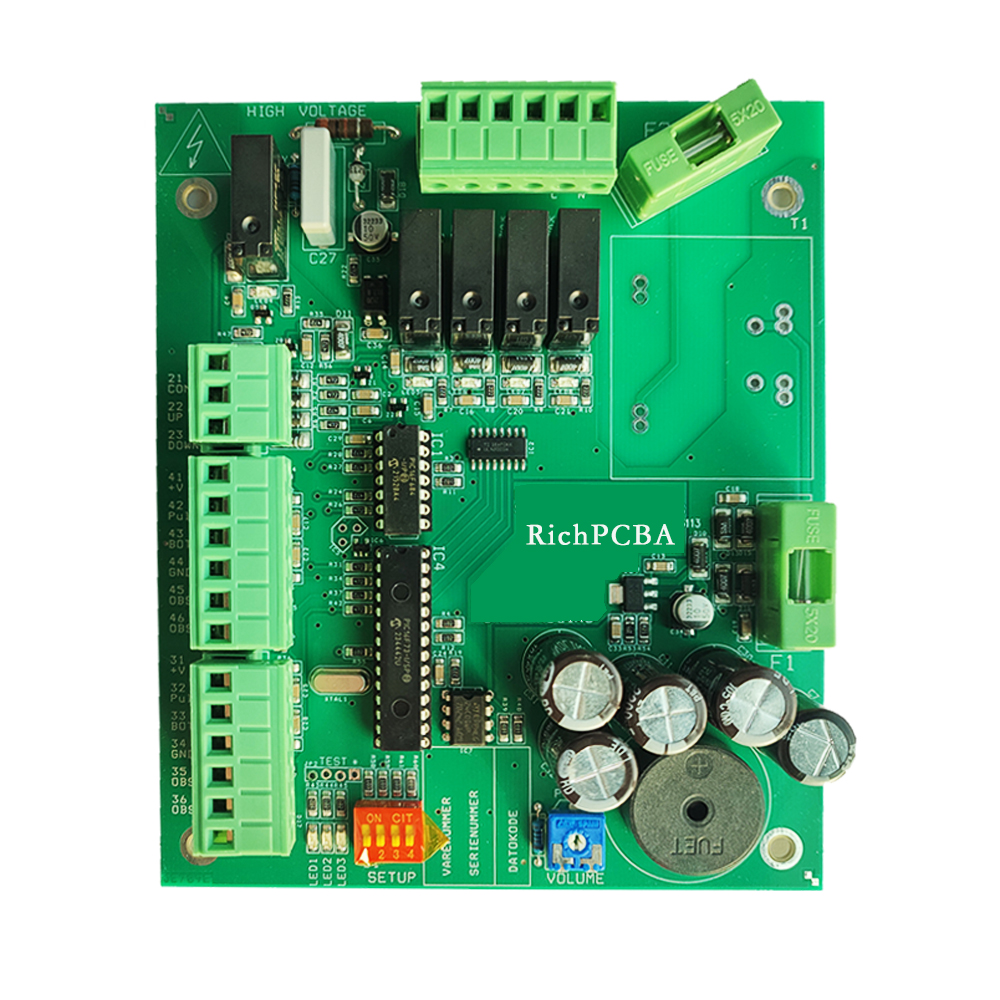

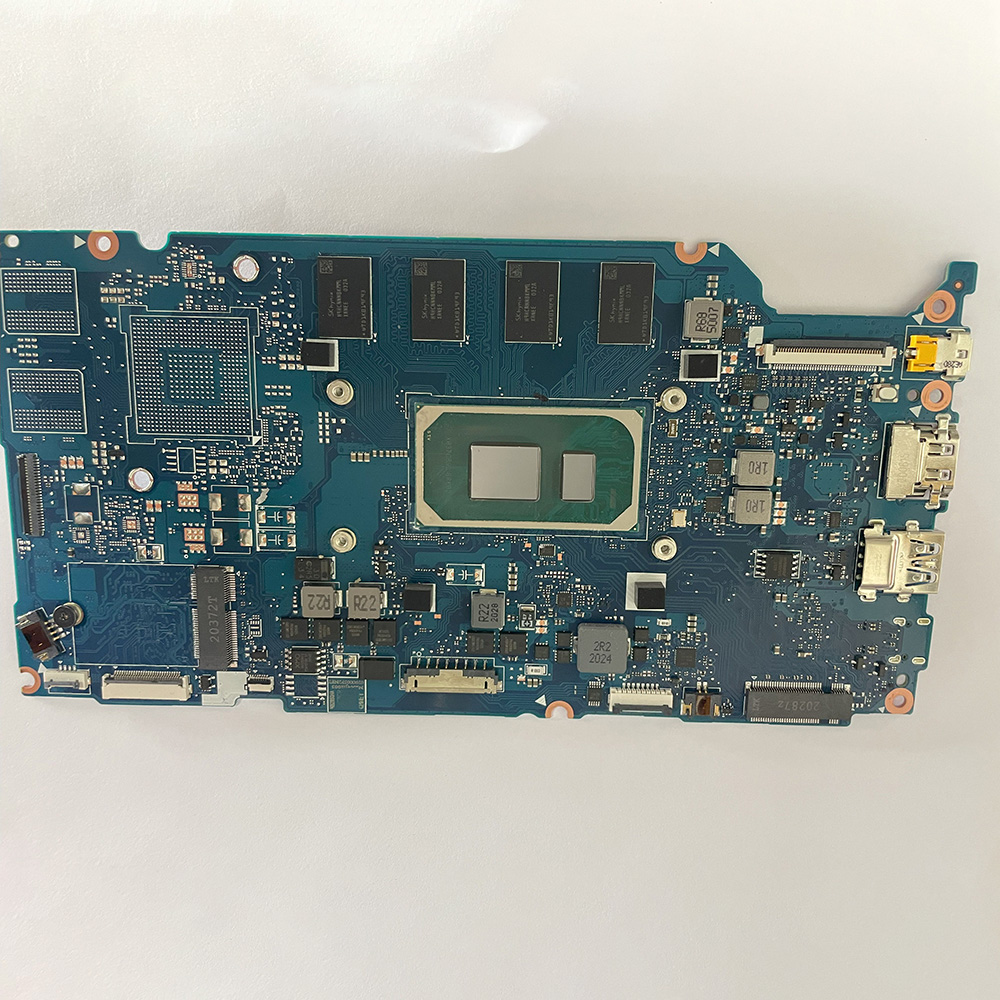

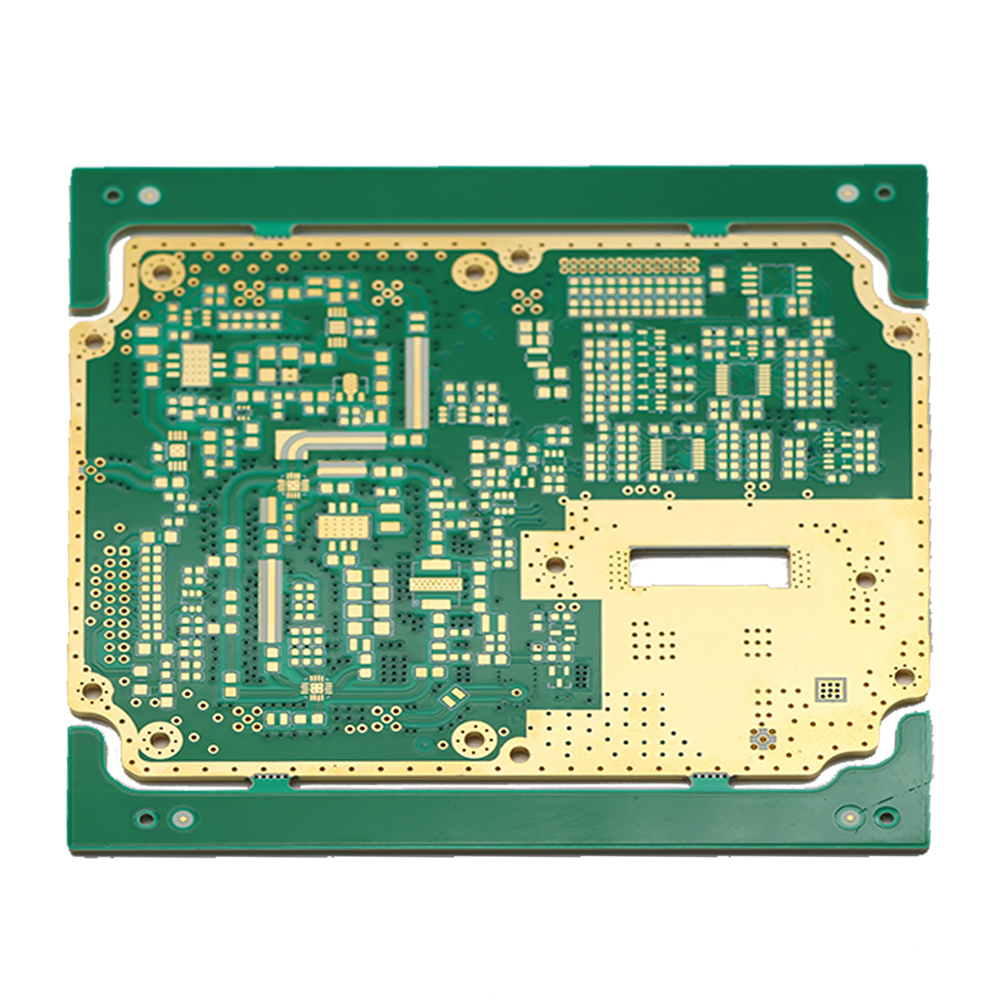

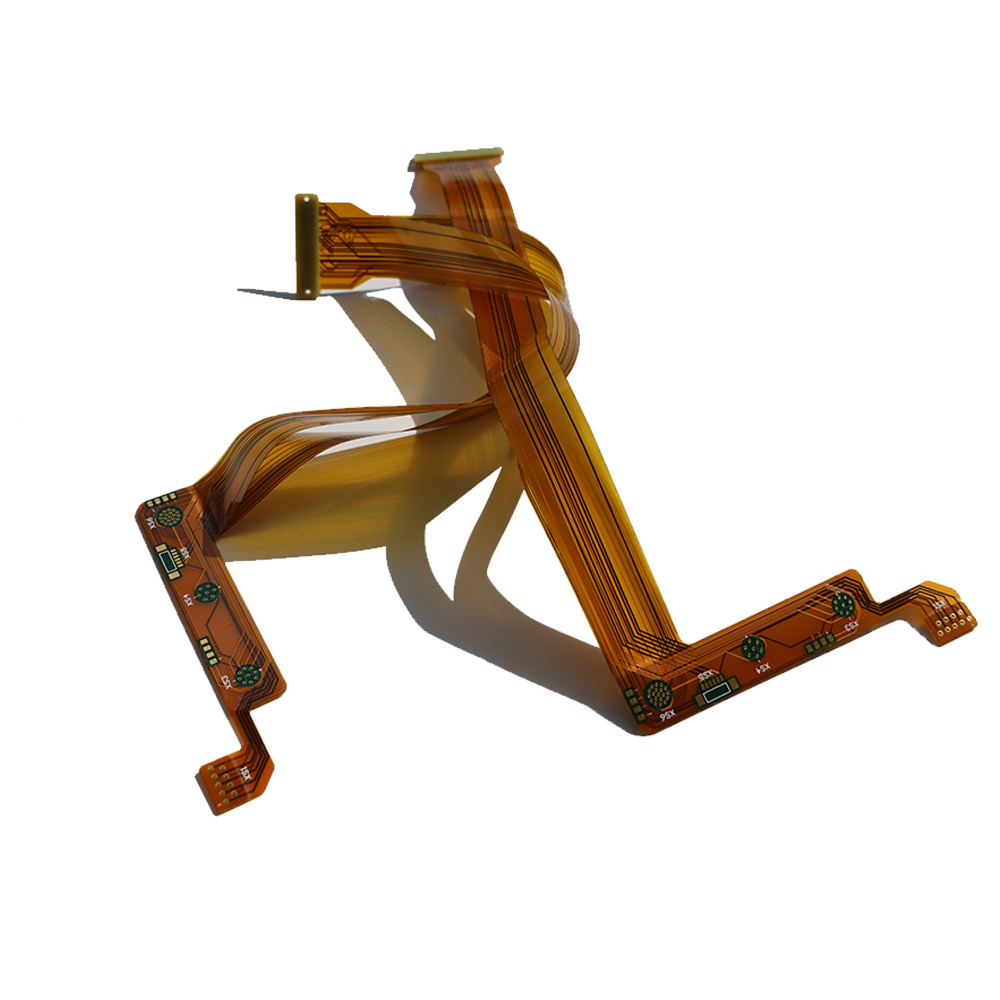

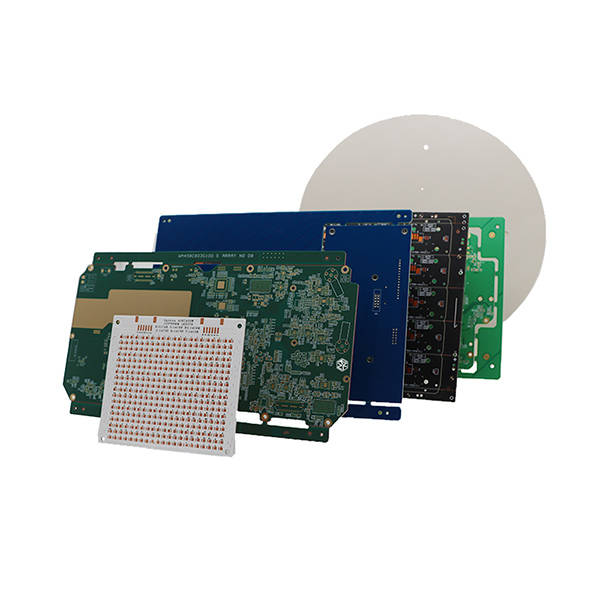

20years+Focus On PCB&PCBAPCB manufacturing PCB assembly one-stop service

-

30000+Customers TrustServing Global and Regional Users

-

800+Professional EngineersStrong Technical Support Team

-

99.6%On-time Delivery RateHigh reliability and short lead time

-

120000㎡Monthly CapacitySuper first-class production equipment escorts excellent quality

Why choose usOur Advantages

-

One-Stop Service

PCB design, PCB manufacturing, PCB assembly, parts sourcing, Capable Of 120,000 M2 PCB Fabrication Per Month, 20 Product Lines For PCBA

-

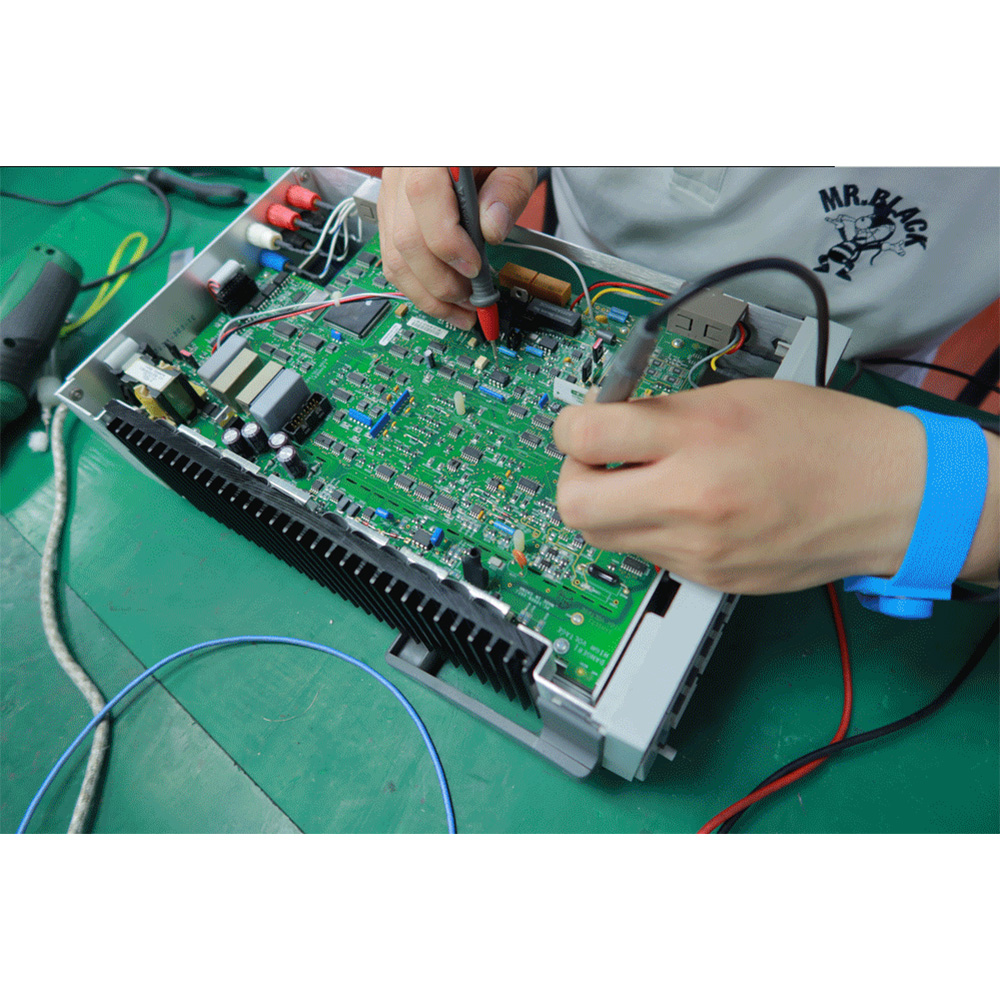

Devoted to High Reliability

Over 20years of in-house fabrication and expertise ensure your PCBs are made to last. 100% quality guaranteed or we’ll remake them free of

-

Fast & Easy

Accept Low Volume & High Volume order started from 1pcs, Get your PCBs manufactured and assembled within 24 hours, Expedite your workflow with competitive lead times.

-

Competitive Price

Reasonable Prices Factory directly, No MOQ, Reliable components sourcing channel, Instant online quote

-

7/24 Online & Tech Support

Respond to your inquiry within 2 hours, we provide 24 hours support for customers in different time zones, Superior One-on-One Service

APPLICATION FIELDS

The applications of automotive PCBA inculde engine control unit (ECU), on board entertainment system, safety system, battery management system (BMS), motor controller, charging system, power distribution module (PDM), inverter and converter, electronic control unit (ECU), vehicle communication system, advanced driving assistance system (ADAS), thermal management system, energy recovery system, etc.

Read moreMedical PCBA is widely used in the medical field, including medical monitoring equipment, medical imaging equipment, surgical instruments, treatment equipment, patient monitors, electrocardiographs, pulse oximeters, sphygmomanometers, ventilators, magnetic resonance imaging (MRI) machines, X-ray machines, CT scanners, radiotherapy machines, endoscopes, robotic surgical assistants, defibrillators, and surgical lighting systems, etc.

Read moreindustry products

OUR LATEST NEWS

GLOBAL COOPERATION

OUR PRODUCTS ARE SPREAD ALL OVER THE WORLD

CUSTOMER FEEDBACKSJOIN US, TO BE OUR HAPPY CUSTOMER!

Pedro From Germany

I wanted to express my gratitude for the PCBA I received a couple of weeks ago. The quality of the product surpassed my expectations, and it has been functioning flawlessly in our devices. The delivery was prompt, and the service provided by your team was exceptional. I am truly satisfied with the overall experience and look forward to continuing our partnership in the future.

Kennedy From Turkey

We have been cooperating with RichPCBA for three years, and their product quality is very stable and their delivery speed is fast. Their service is always satisfactory, and you can rest assured to choose them as your partner.

Eric From france

The logistics is super fast, the quality is very good, the quality is better than the previous supplier, and you can cooperate for a long time, give RICHPCBA a thumbs up

Lily From Australia

The customer services you provide is unparalleled. No matter whatwe need, you are always happy to help. Thanks for your great job!

Pedro From Germany

I wanted to express my gratitude for the PCBA I received a couple of weeks ago. The quality of the product surpassed my expectations, and it has been functioning flawlessly in our devices. The delivery was prompt, and the service provided by your team was exceptional. I am truly satisfied with the overall experience and look forward to continuing our partnership in the future.

Kennedy From Turkey

We have been cooperating with RichPCBA for three years, and their product quality is very stable and their delivery speed is fast. Their service is always satisfactory, and you can rest assured to choose them as your partner.

Алексей From Russia

We are very satisfied with the PCBA products we purchased from your company, and we are deeply impressed by the product quality and service. We thank your company for being proactive attitude and efficient product delivery. We look forward to establishing a closer working relationship in the future. Please convey our gratitude and praise to all employees of your company for their hard work and professionalism

Bill From USA

RichPCBA is easy to work with, veryflexible and customer oriented, andalways willing to push for on time delivery.They were goodqualityand worked well. You did good job. l would like get a quote againonce next design is ready

Eric From france

The logistics is super fast, the quality is very good, the quality is better than the previous supplier, and you can cooperate for a long time, give RICHPCBA a thumbs up

Lily From Australia

The customer services you provide is unparalleled. No matter whatwe need, you are always happy to help. Thanks for your great job!

Pedro From Germany

I wanted to express my gratitude for the PCBA I received a couple of weeks ago. The quality of the product surpassed my expectations, and it has been functioning flawlessly in our devices. The delivery was prompt, and the service provided by your team was exceptional. I am truly satisfied with the overall experience and look forward to continuing our partnership in the future.

Kennedy From Turkey

We have been cooperating with RichPCBA for three years, and their product quality is very stable and their delivery speed is fast. Their service is always satisfactory, and you can rest assured to choose them as your partner.

Eric From france

The logistics is super fast, the quality is very good, the quality is better than the previous supplier, and you can cooperate for a long time, give RICHPCBA a thumbs up

Lily From Australia

The customer services you provide is unparalleled. No matter whatwe need, you are always happy to help. Thanks for your great job!