0102030405

knowledge

What is via in PCB?

2024-07-25

Vias are the most common holes in PCB production. They connect the different layers of the same network but are usually not used for solder components. Vias can be divided into three types: through holes, blind vias, and buried vias. The details information for these three vias is as below:

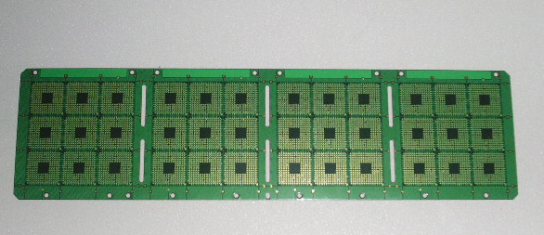

What is a printed circuit board?

2024-07-24

PCB Trace Manufacturing Process: Equipment, Techniques, and Key Considerations

The manufacturing of Printed Circuit Board (PCB) traces is a critical step in the PCB production process. This process involves multiple stages, from circuit design to the actual formation of traces, ensuring that the final product performs reliably. Below is a detailed summary of the equipment, processes, and key considerations involved in trace manufacturing.

The Importance of High-Frequency PCBs in Electronics Manufacturing

2024-07-17

As electronics continue to advance in complexity and demand faster signal transmission rates, high-frequency PCBs have become a crucial component in the development of high-performance applications across the manufacturing sector.

High-frequency printed cir...

view

detail

High Frequency PCB Design: Expert Tips and Best Practices

2024-07-17

Designing PCBs for High Frequency

When it comes to creating a PCB for high frequency applications, there are several important factors to consider. These include selecting the right materials, surface finish, and understanding the difference between hig...

view

detail

High-Frequency PCB Design and Assembly: Key Materials

2024-07-17

High-frequency printed circuit boards (PCBs) are vital components in a range of applications, including telecommunications, radar systems, wireless communication, and high-speed data processing. The performance of these PCBs is heavily influenced by the mate...

view

detail

Analysis and Mitigation of Power Supply Noise in High-Frequency PCB Design Process

2024-07-17

In high-frequency PCBs, power supply noise stands out as a significant form of interference. This article conducts a comprehensive analysis of the characteristics and origins of power supply noise in high-frequency PCBs, and offers practical and effective solu...

view

detail