01

Flexible Printed Circuit Board, FPC Double-sided Board

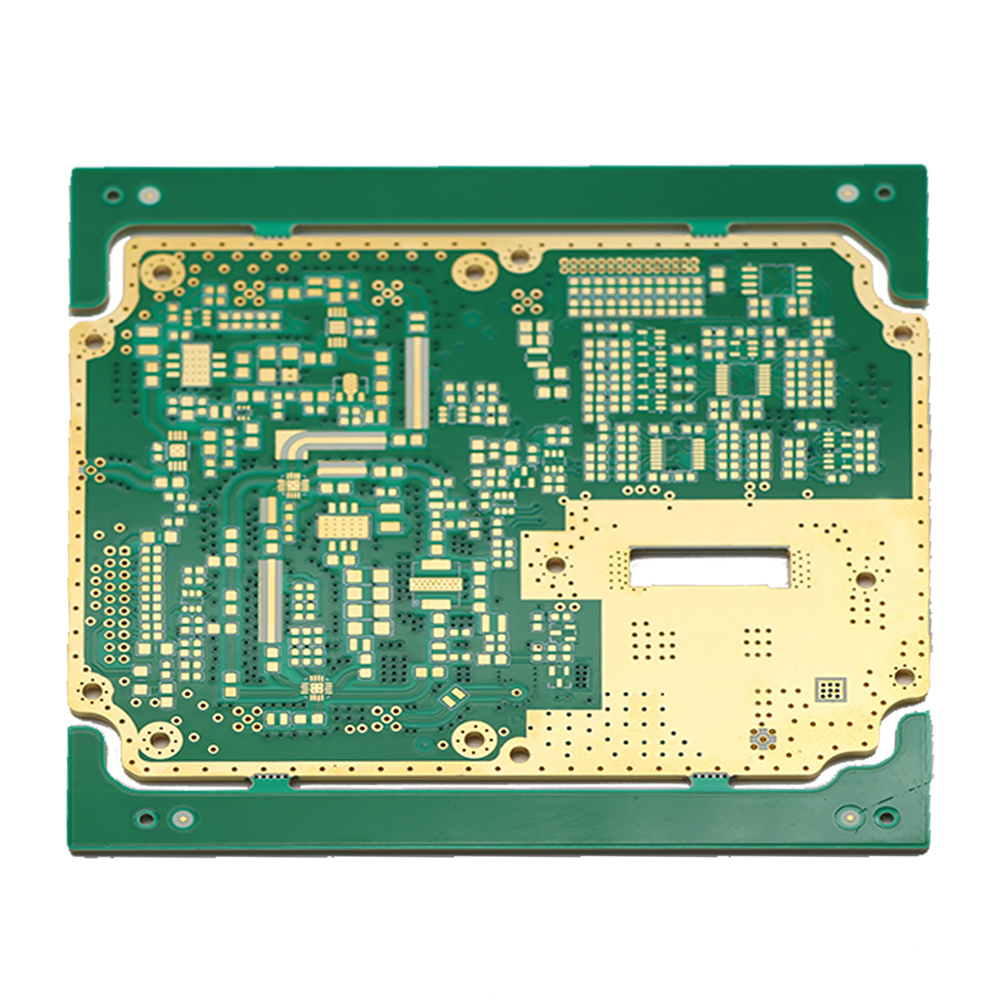

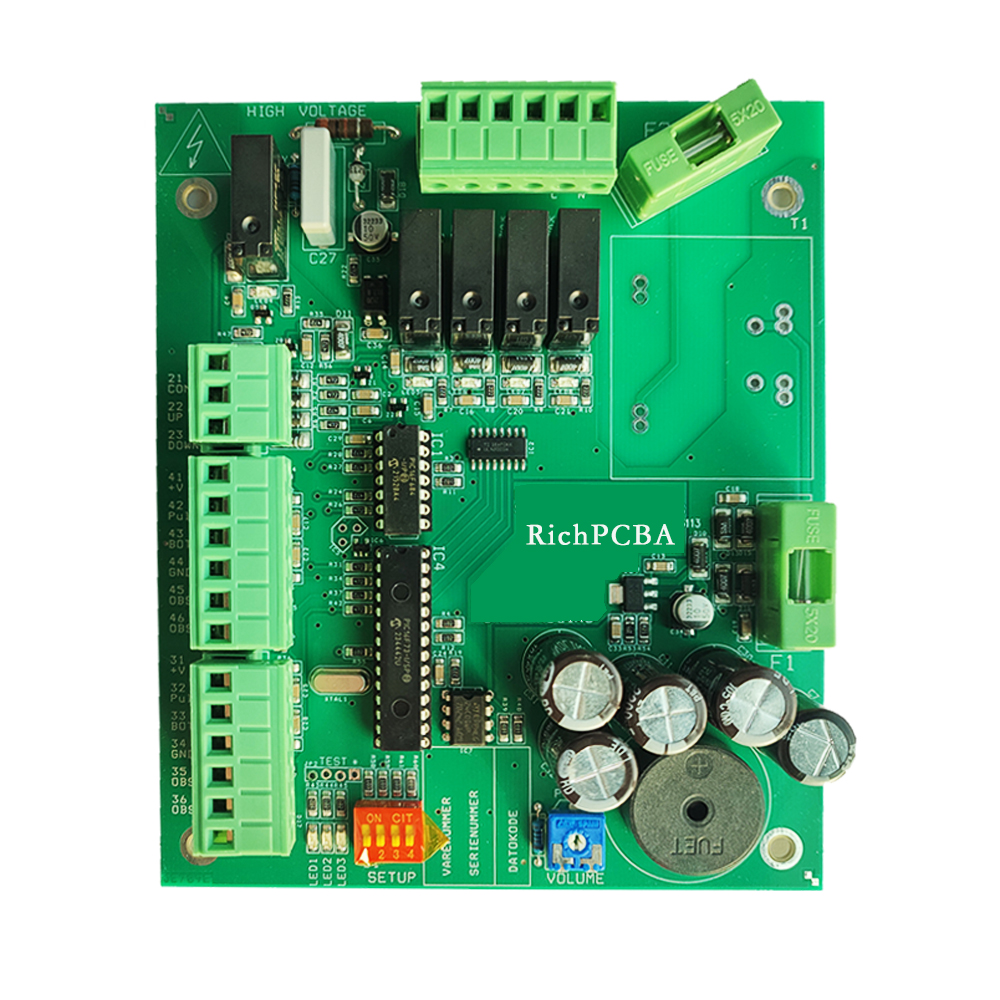

Definition of FPC(see figure 1 for details)

1.FPC—Flexible Printed Circuit, a highly reliable and flexible printed circuit made by etching onto copper foil using polyester film or polyimide as the substrate to form a circuit.

2.Product Characteristics : ① Small size and light weight : meeting the needs of high-density, miniaturization, lightweight, thinness and high reliability development directions; ② High flexibility : can move and expand freely in 3D space, achieving integrated component assembly and wire connection.

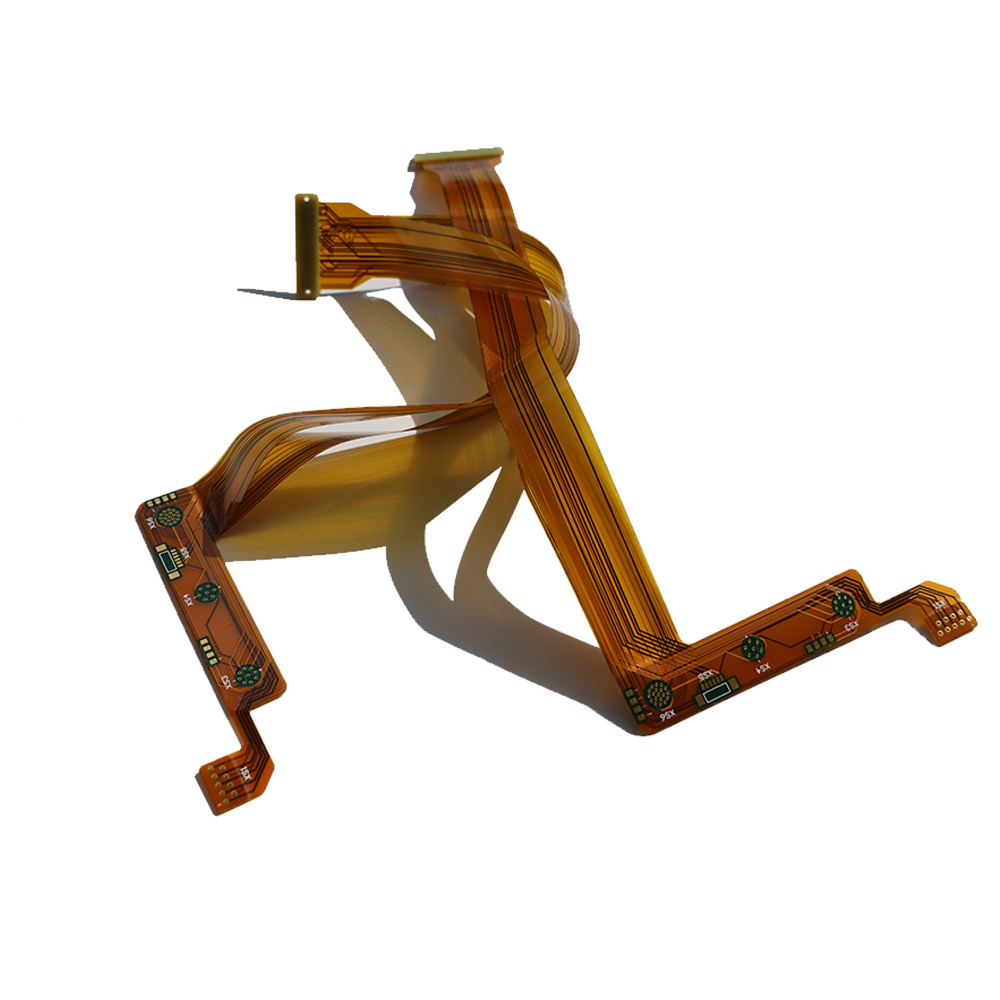

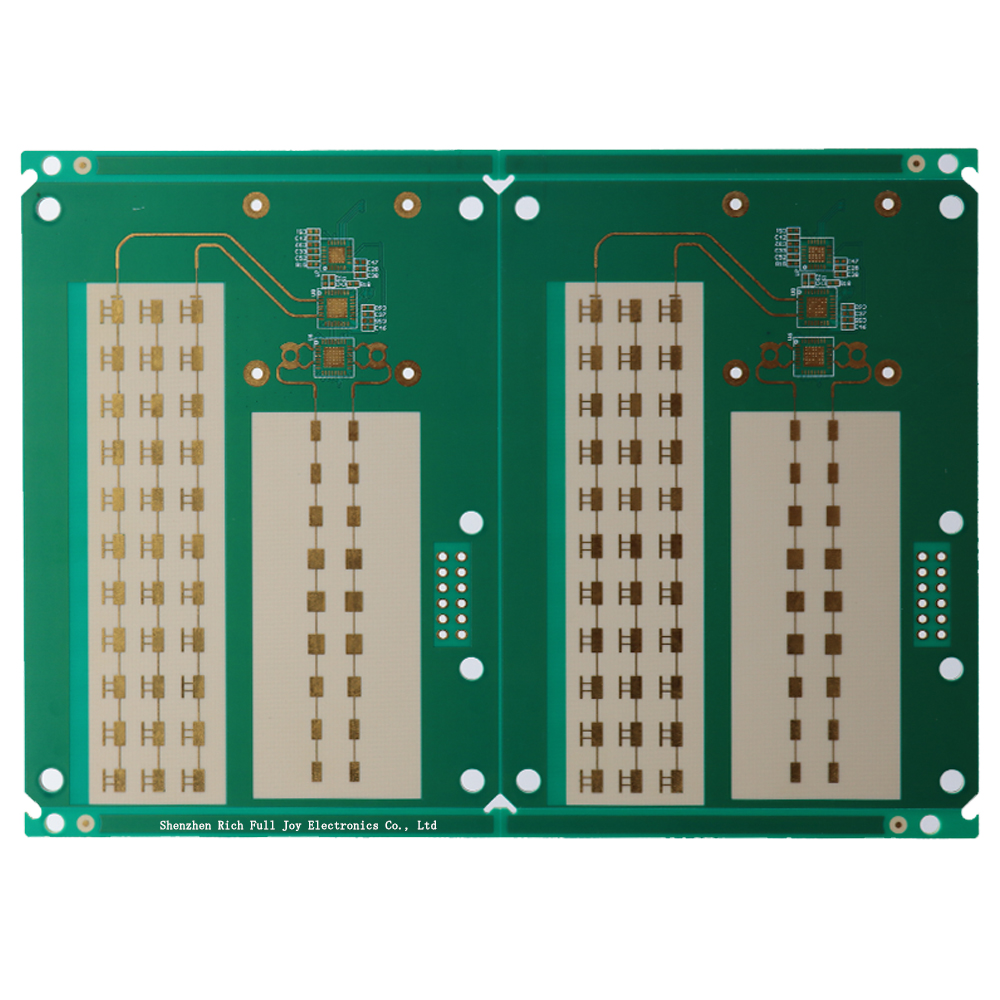

FPC classification +FPC basic materials (see figure 2 for details)

According to the number of conductive layers, it can be divided into single-sided board, double-sided board and multi-layer board.

Single-sided board : conductor on one side only.

Double-sided board : there’re 2 conductors on both sides, and to establish electrical connection between 2 conductors with through hole (via) as a bridge. A through hole is a small copper plated hole on the hole wall that can be connected to the circuits on both sides.

•Multi-layer board : contains 3 or more layers of conductors, with more precise layout.

•Except single-sided board, the number of layers of rigid board is generally even, such as 2, 4, 6, 8 layers, mainly because the odd layer stacking structure is asymmetric and prone to board warping. On the other hand, flexible PCB is different as there’s no problem of warping, so 3-layer, 5-layer, etc. are common.

Copper foil is devided into Electro-Deposited copper(ED Copper) and Rolled Annealed copper(RA Copper)

| Comparison between RA copper and ED copper | ||

| Cost | high | low |

| Flexibility | good | poor |

| Purity | 99.90% | 99.80% |

| Microscopic structure | sheet-like | columnar |

So the application of dynamic bending must use RA copper, such as the connection plate for folding/sliding phones and the expansion&contraction parts of digital cameras. In addition to its price advantage, ED copper is also more suitable for the production of micro circuits due to its colomnar structure.

| Adhesive Substrate | Adhesiveless Substrate | |||

| PI | AD | CU | PI | CU |

| 0.5mil | 12um | 1/3OZ | 0.5mil | 1/3OZ |

| 13um | 0.5OZ | 0.5OZ | ||

| 1mil | 13um | 0.5OZ | 1mil | 1/3OZ |

| 20um | 1OZ | 0.5OZ | ||

Conventional Substrate Configuration

The commonly used thickness specifications for the base copper of soft boards include 1/3oz, 0.5oz, 1oz and other thickness specifications. Unconventional copper thicknesses include 1/4oz, 3/4oz and 2oz, etc.

Application

Camera, video camera, CD-ROM, DVD, hard drive, laptop, telephone, mobile phone, printer, fax machine, TV, medical equipment, automotive electronics, aerospace and industrial control, new energy products.