01

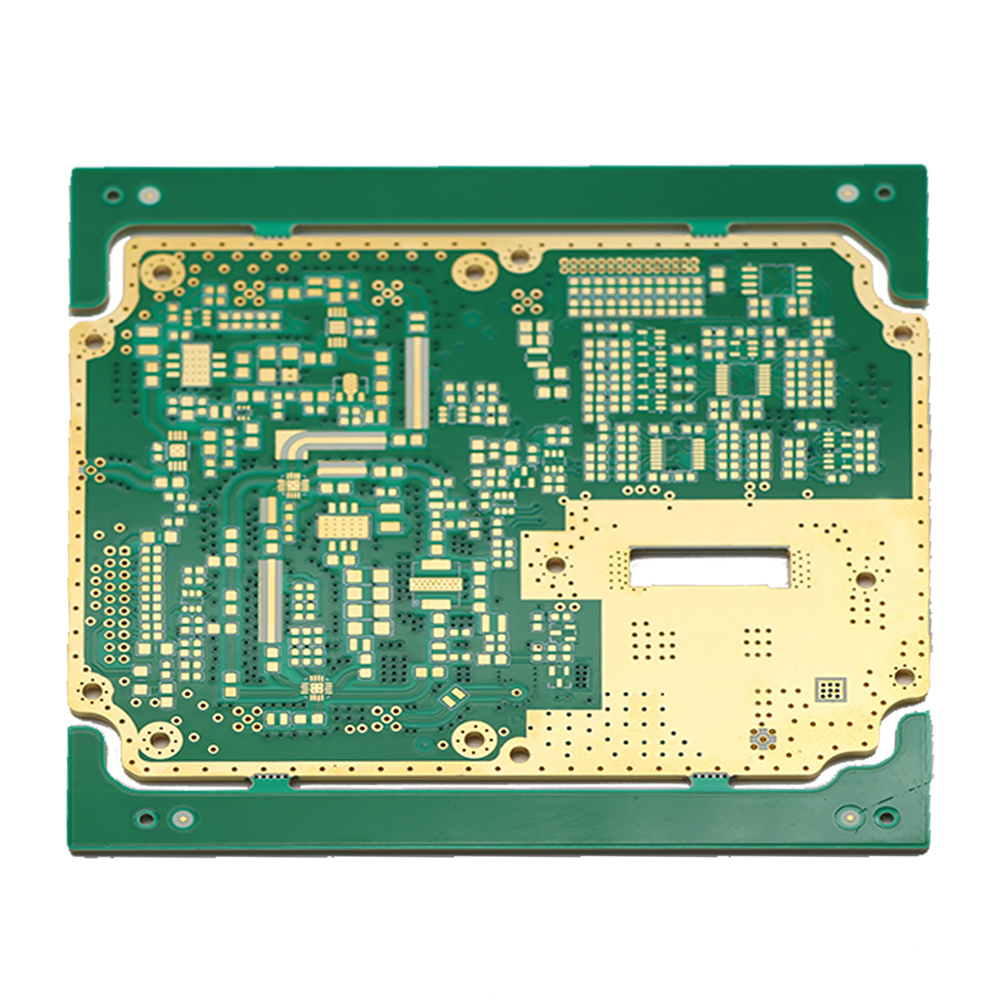

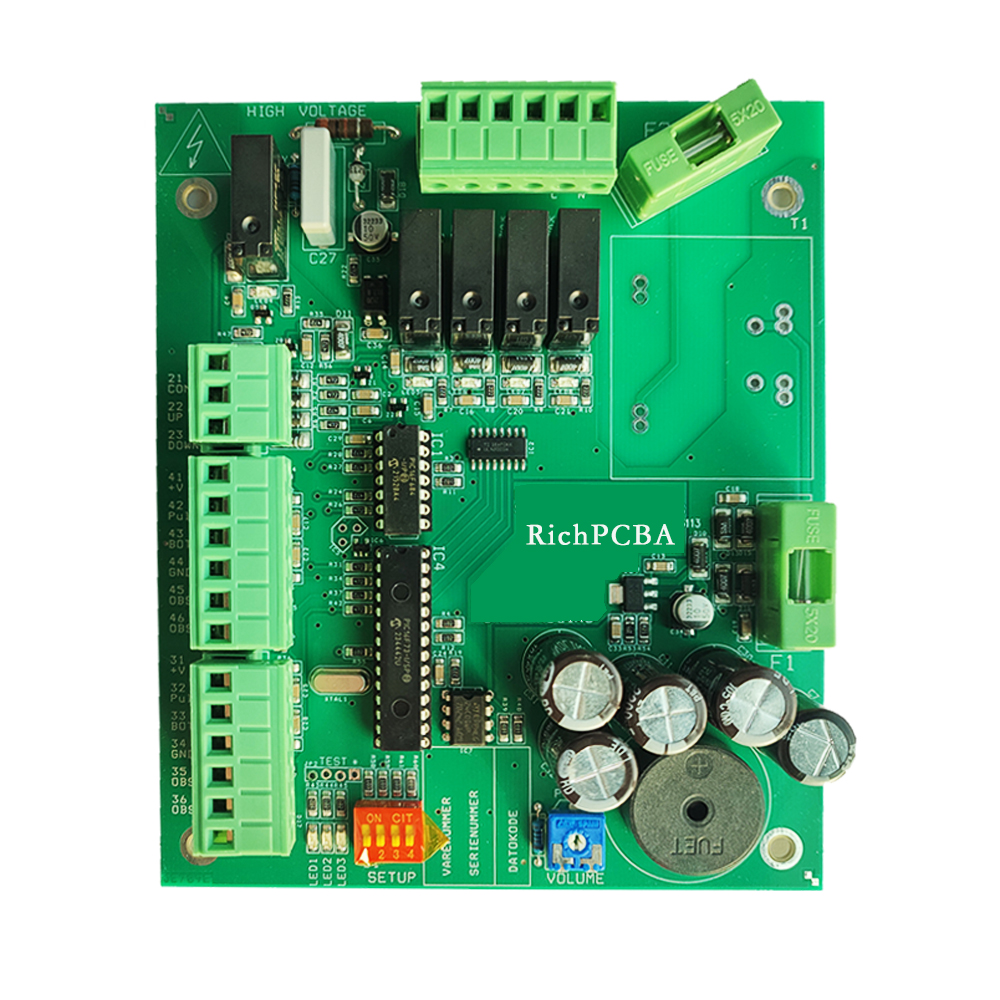

Rogers Microwave RF Automotive Radar PCB

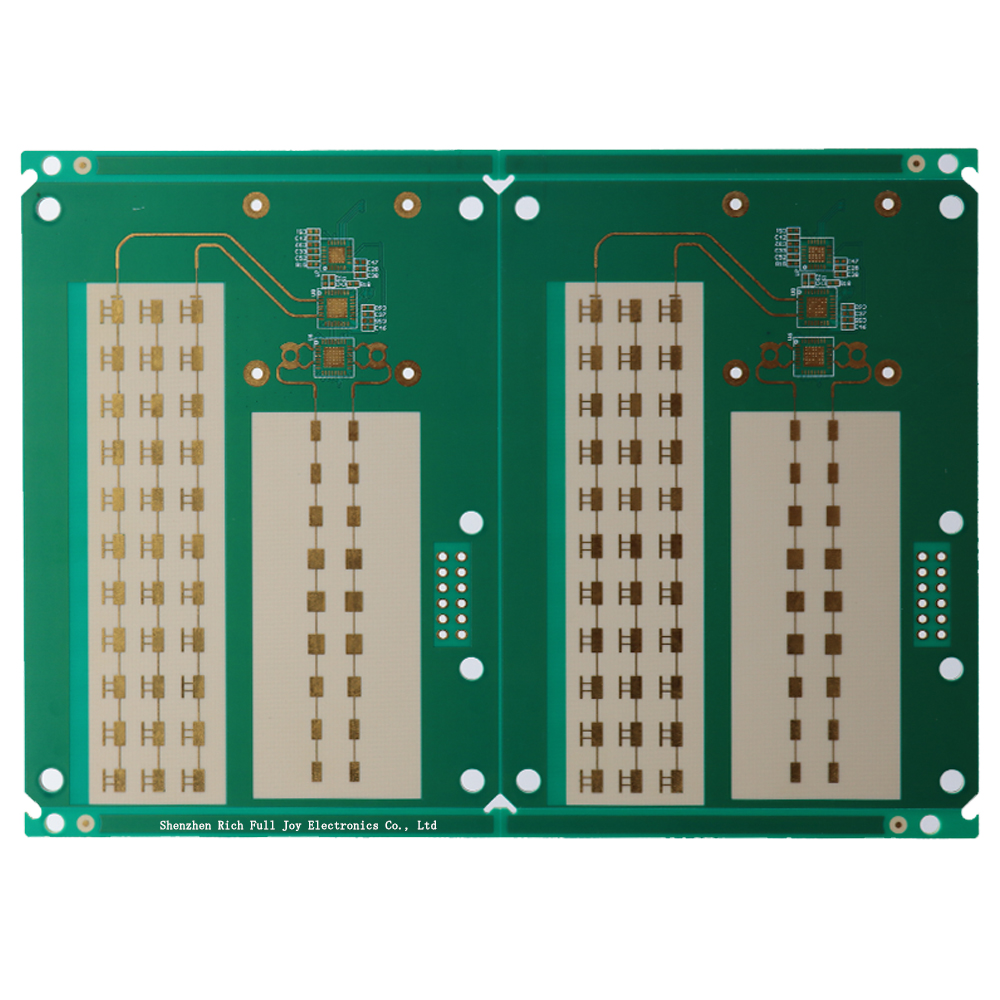

High-frequency PCB for Millimeter Wave Automotive Radar

5G and mobile travel are products of the deep integration of the automotive industry with new generation information technologies such as communication, artificial intelligence and high-performance computing of the IoTs. They are the main directions for the intelligent and networked development of the global automotive and transportation fields. The autonomous vehicle equipped with 5G technology can achieve safer driving and more comfortable riding experience. Faster 5G signal transmission will give the vehicle system more time to provide feedback and processing, thereby ensuring driving safety and providing a more efficient driving experience.

The main application in autonomous driving is millimeter wave radar sensors, which mainly use materials such as RO3003G2TM, RO3003TM, RO4830TM, CLTE-MWTM, etc. They are widely used in 77GHz millimeter wave radar and have very stable dielectric constant and ultra-low dissipation factor (a dissipation factor of 0.001 is commonly tested at 10 GHz). At the same time, the structure without glass fiber further reduces the variation of local dielectric constant in the millimeter wave frequency band, Eliminating the fiberglass effect of the signal further increases the phase stability of the radar sensor.

With the development of radar sensors in the 79 GHz frequency band (77-81 GHz), their wider signal bandwidth can further improve the resolution of radar sensors, increase scanning angles, and even achieve 4D imaging.

Rogers PCB for millimeter wave radar sensor (see figure 1 and 2 for details)

Specification parameter table of (Rogers)RO3003™ High-frequency PCB

(Rogers) RO3003™ High frequency substrates are PTFE composite materials filled with ceramics, used for PCBs in commercial microwave and RF applications. The unique design endows the material with stability and eliminates the step change in dielectric constant of general-purpose PTFE materials at room temperature.

Rogers RO3003™ High frequency substrates still have stable dielectric constants (Dk: 0.00+/-0.04) and dissipation factor (Df: 0.0010 at 10GHz ) at different temperatures and frequencies. Very suitable for applications such as automotive millimeter wave radar (77 GHz), advanced driving assistance systems (ADAS) and 5G wireless infrastructure (millimeter wave).

RO3003™ substrate has excellent mechanical stability, making it convenient for designers to use materials with different dielectric constants in a single-layer circuit when designing multi-layer circuits without warping or reliability issues. The thermal expansion coefficient of RO3003™ substrate in the X/Y direction is 17/16 (ppm/℃). This value is equivalent to the thermal expansion coefficient of copper, so the typical value of etching shrinkage (baking after etching) of the material is less than 0.5mils/inch, demonstrating excellent dimensional stability. The CTE in the Z direction is 25 (ppm/℃), and even in harsh temperature environments, this material can still ensure the stability of electroplated through holes.

Figure 1 : Temperature dependent variation of dielectric constant of RO3003 and RO3035 laminates

As shown in the above figure, the dielectric constants of the RO3003 and RO3035 laminates exhibit good stability with temperature. There is no step change in dielectric constant at room temperature like PTFE glass fiber.

Figure 2 : Dissipation factor of RO3003 and RO3035.

The above figure indicates the distribution of dissipation factors in the RO3003 and RO3035 laminates. RO3003-RO3035 Test method: IPC-TM-65025.5.5 Test conditions: 10 GHz 23 °C.

Application

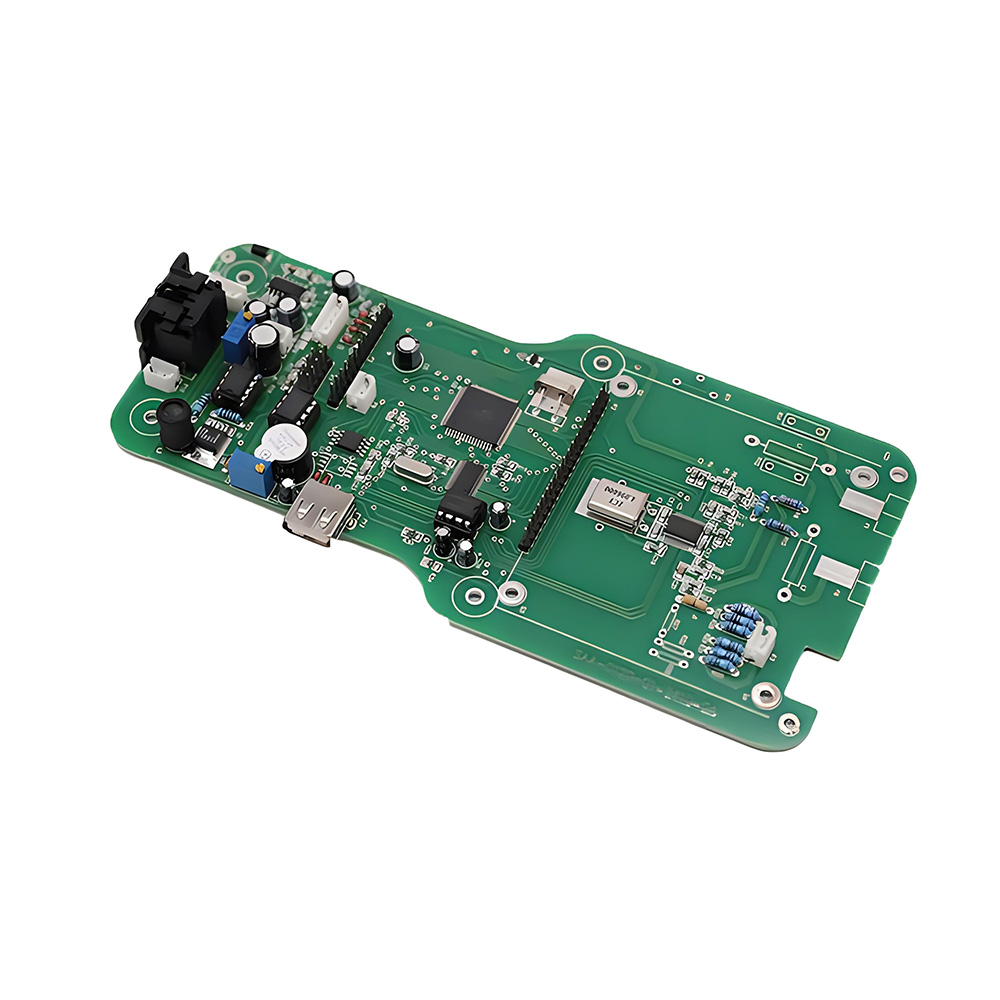

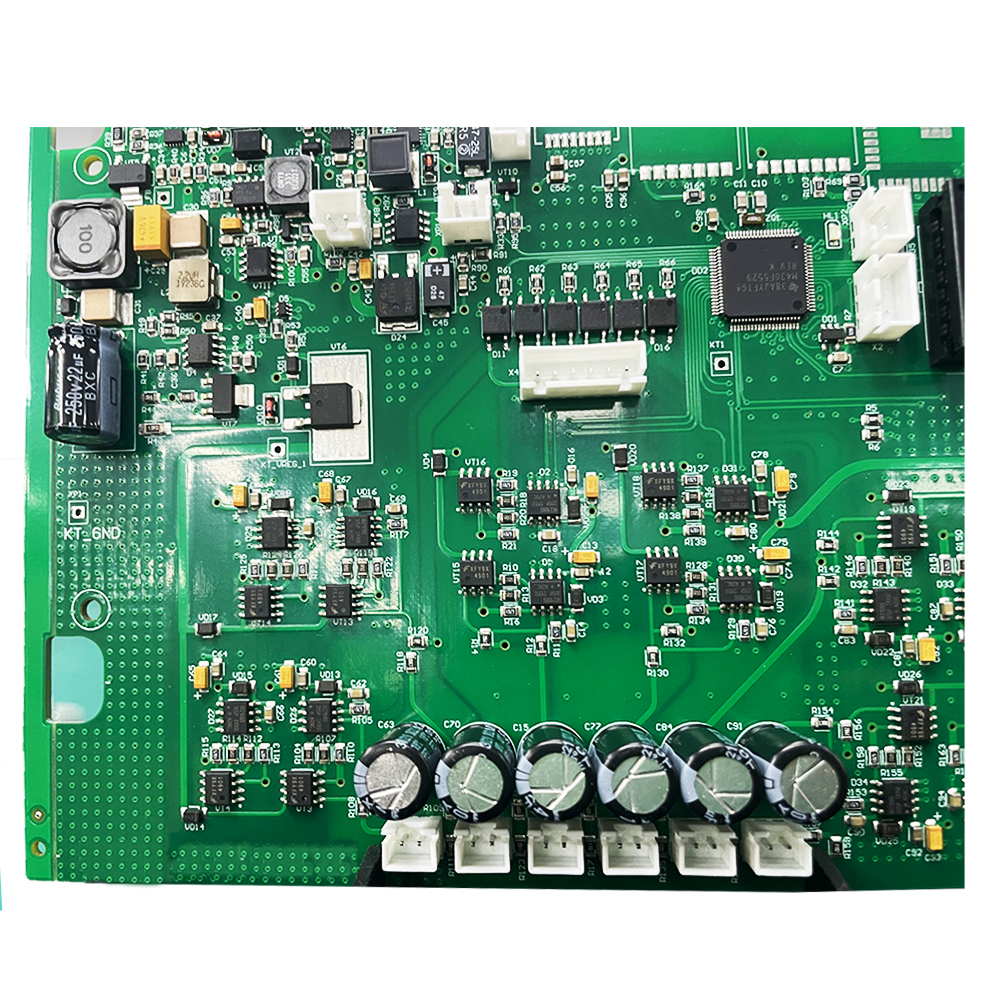

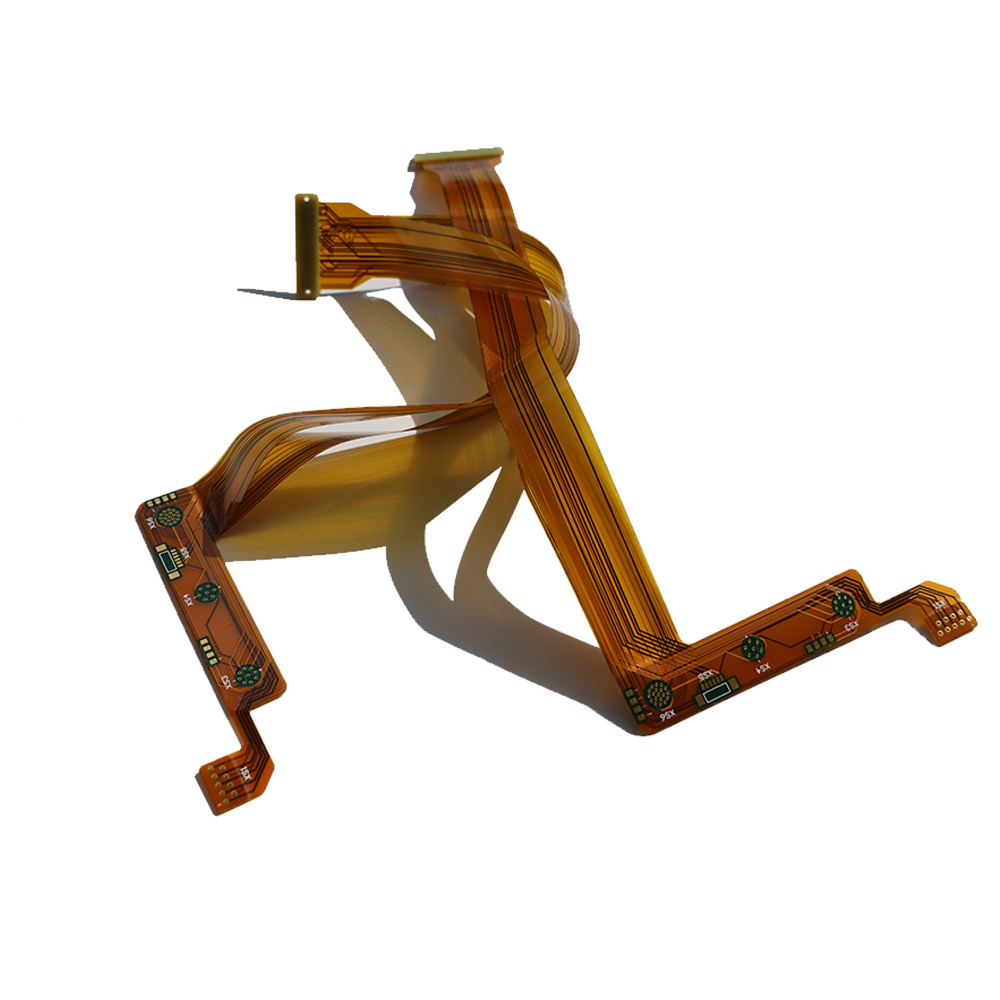

Application of High-frequency substrate (see figure 3-1 for details)

Common brands of high-frequency substrates: ARLON high-frequency substrate, TACONIC high-frequency substrate, ROGERS high-frequency substrate, Shengyi, Taiguang, Taiyao, Fushide, Wangling and many other brands. Company stock: Rogers, Taconic, F4B, TP-2, FR-4 and other high-frequency substrates, expedited sampling within 24 hours.

Rogers, as a leading global supplier of specialty substrates, has a market share of over 50% worldwide and 20 years of industry experience in the field of base station antenna RF.

Rogers high-frequency materials are composed of 3000 series, 4000 series, 5000 series, etc.

RICHPCBA specializes in manufacturing 2-68 layer microwave RF PCBs and other products, with Rogers high-frequency materials readily available, imported in their original packaging with a complete range of models. We provide Rogers high-frequency PCB sampling, production and processing services.

Application fields of high-frequency PCBs: widely used in communication equipment, industrial control, smart homes, customized power supplies, medical machinery and other fields.

Automotive radar; GPS antenna; Mobile communication system : power amplifier and antenna; Mounted antenna for wireless communication; Satellite for direct transmission; Cable system for data linking; Remote meter reader and power backboard, etc;