0102030405

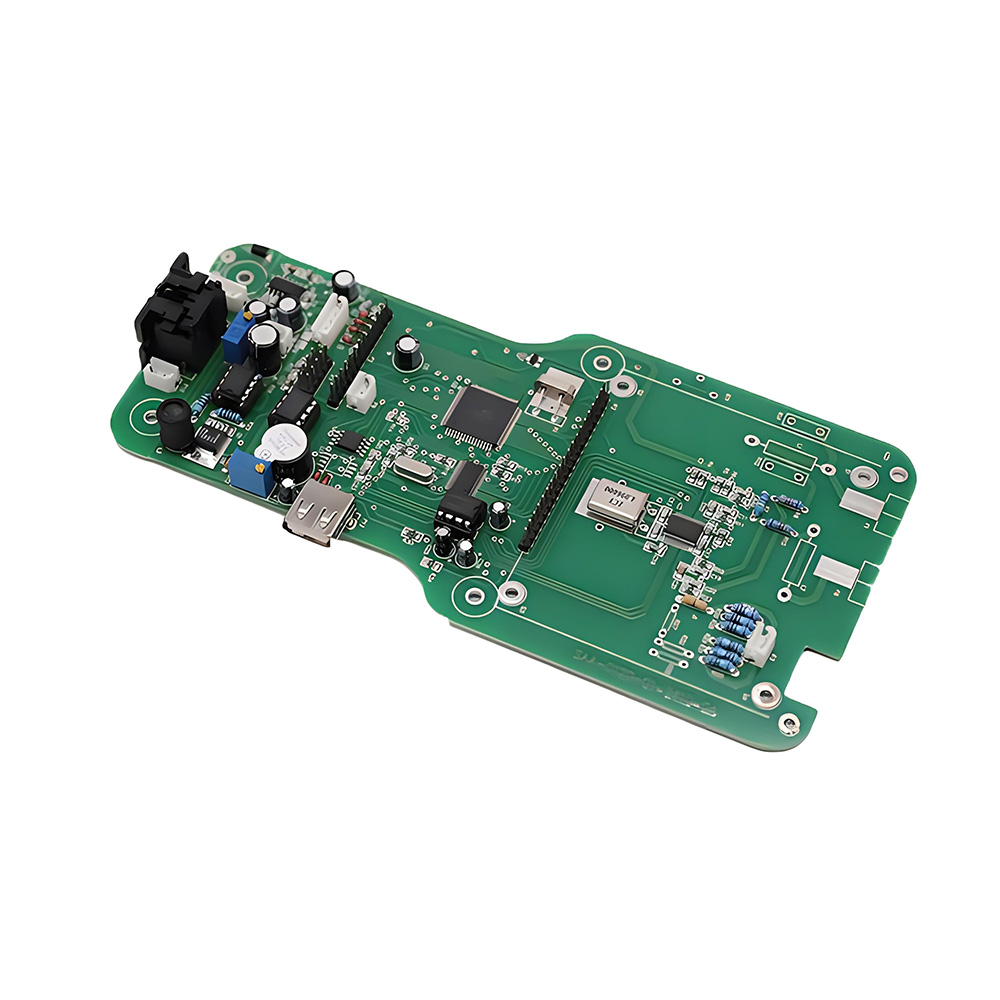

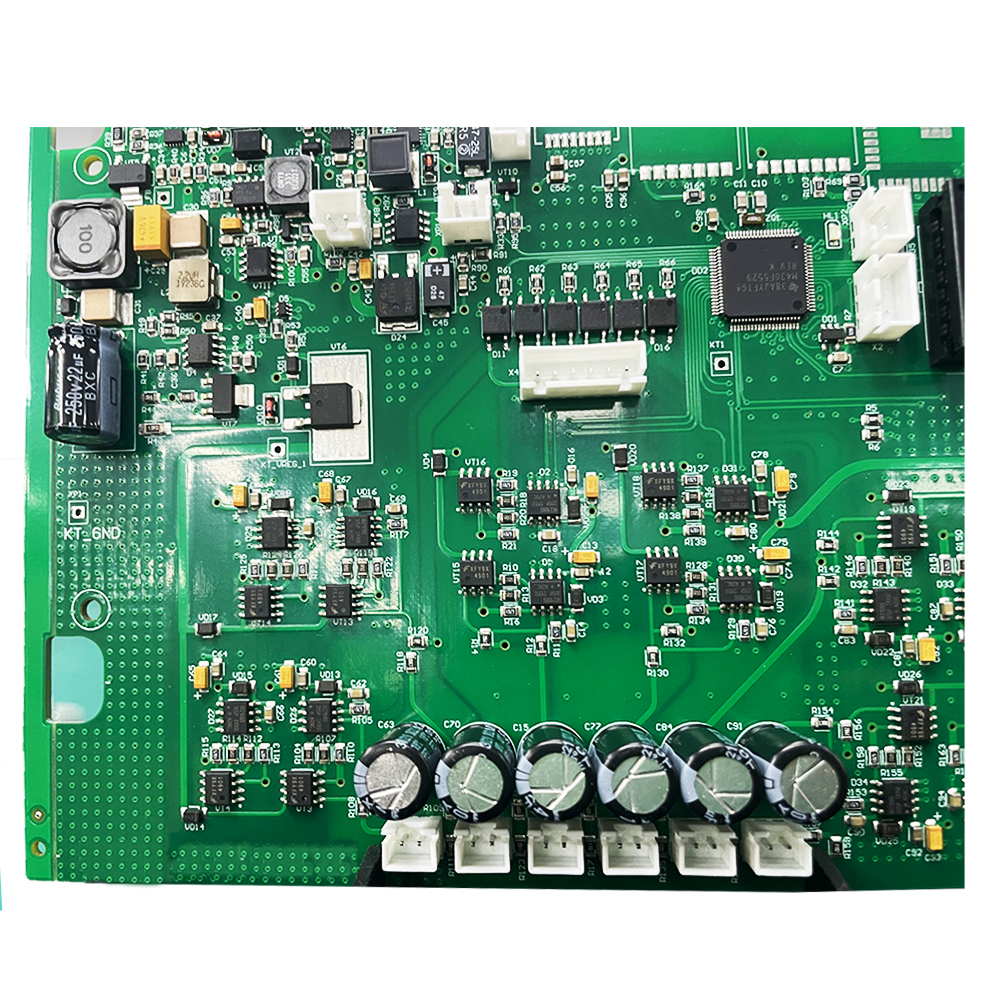

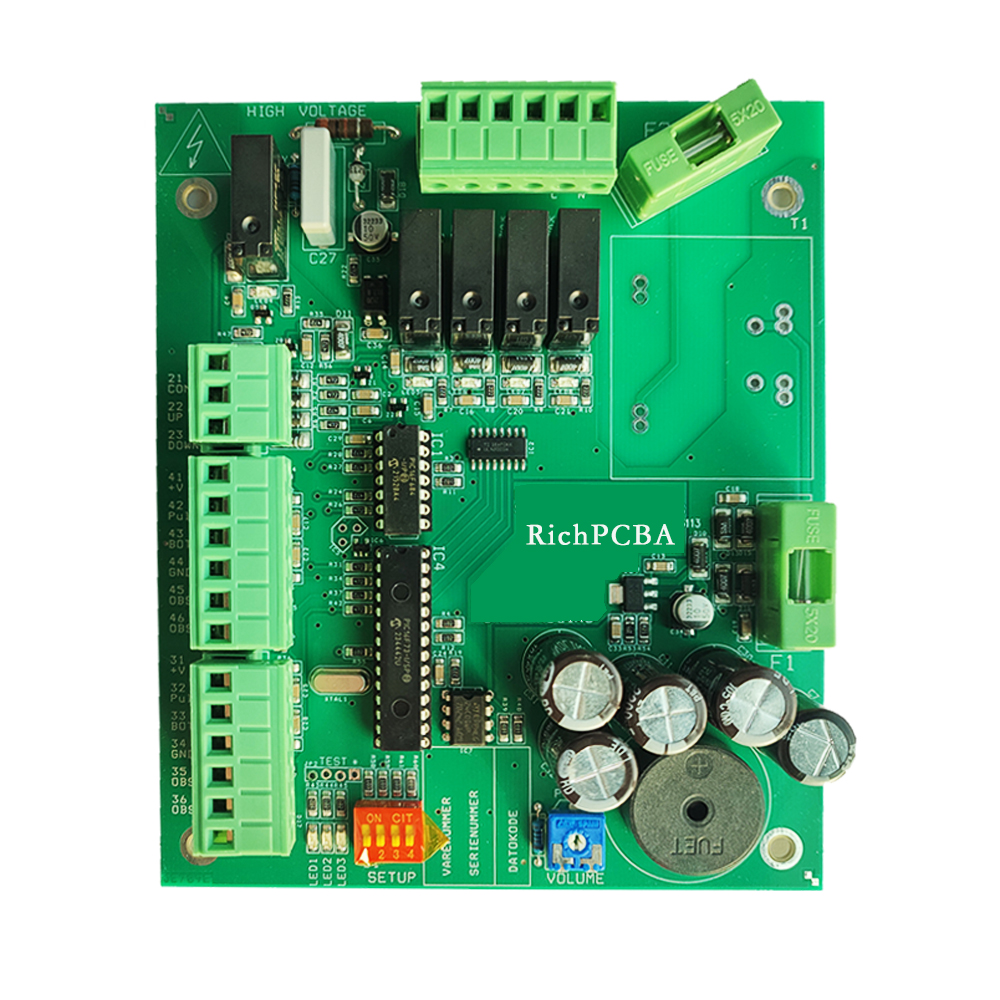

PCBA for Medical Electronics / Control Board of Medical Equipment

Manufacturing Process of Medical Equipment PCBA

1. PCB design: Based on the requirements and specifications of the equipment, engineers will use professional software to design circuit boards.

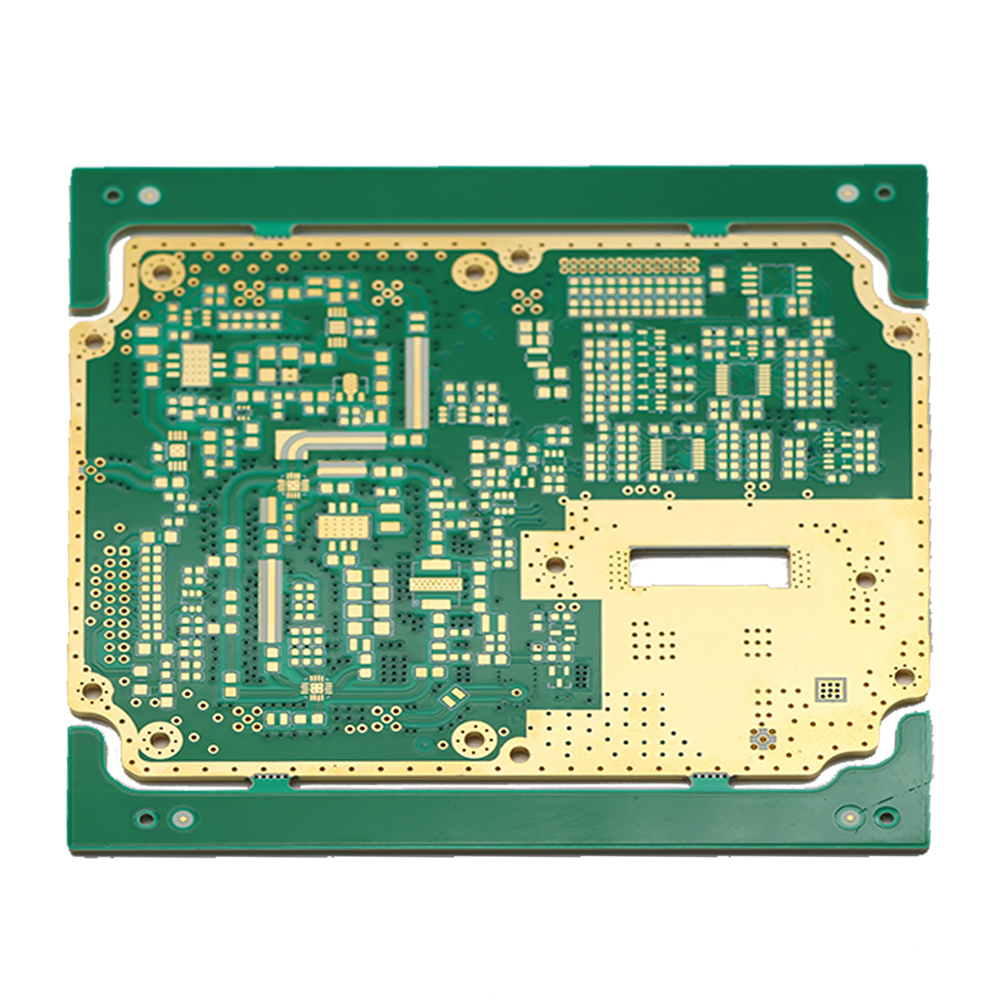

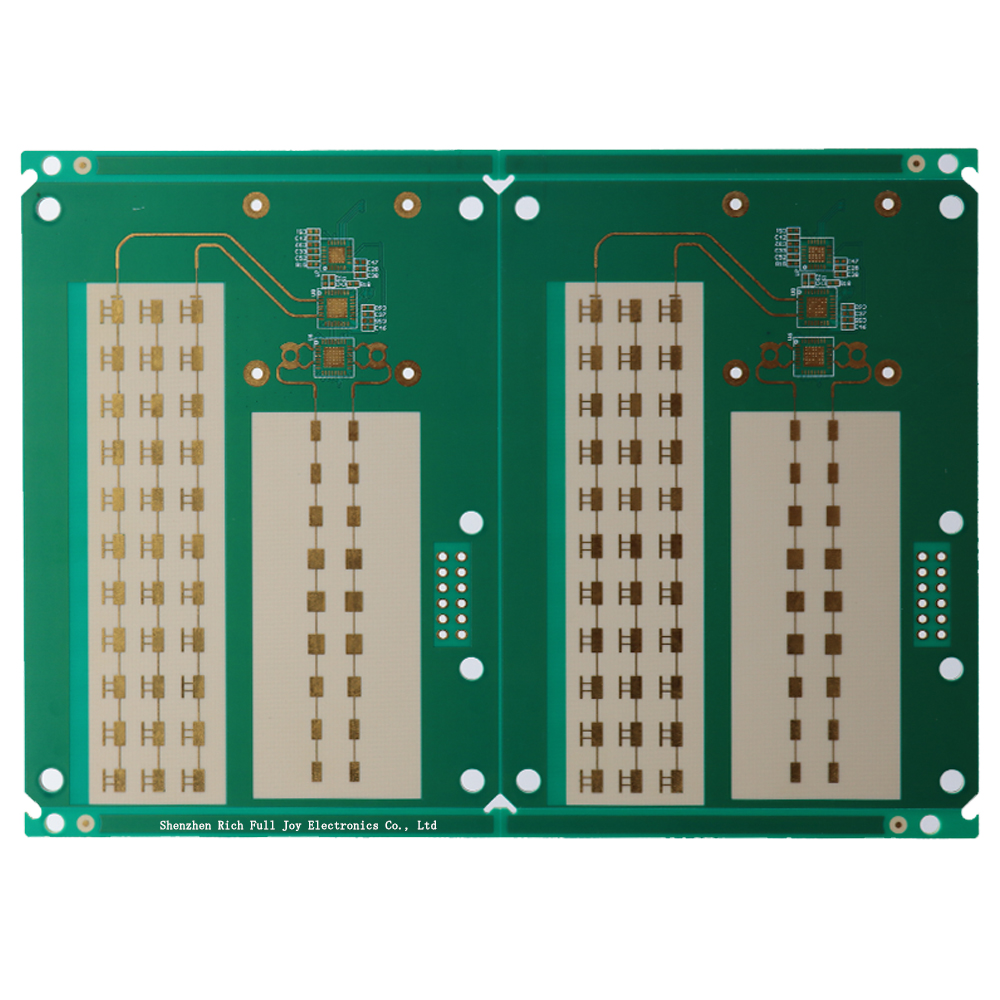

2. PCB manufacturing: After the design is completed, our company manufactures bare boards based on the PCB design drawings.

3. Component procurement: The procurement team purchases the required electronic components based on the BOM (Bill of Materials). These components may include resistors, capacitors, inductors, ICs (integrated circuits), etc.

4. SMT mounting: Use a mounting machine to accurately mount electronic components onto a PCB. This process is automated, ensuring speed and accuracy.

5. Soldering: Solder components and PCBs together through reflow soldering or other welding methods.

6. Testing and Quality Inspection: Use AOI (Automatic Optical Inspection) equipment and other testing tools to conduct quality and functional testing on the welded PCBA, ensuring that it meets design requirements and quality standards.

7. Assembly and packaging: Assemble the qualified PCBA with other components (such as display screens, batteries, etc.) to form a complete medical device.

Check it out what requirements in the medical industry the PCB assembly and manufacturing meet

With the aging population, the importance of PCB manufacturing in the healthcare industry will continue to grow. For example, in medical imaging units such as MRI and cardiac monitoring equipment such as pacemakers, PCB circuit boards play a crucial role. Even temperature monitoring devices and responsive neural stimulators can achieve state-of-the-art PCB technology and components. Today, let's discuss the role of PCB in the medical industry together through.

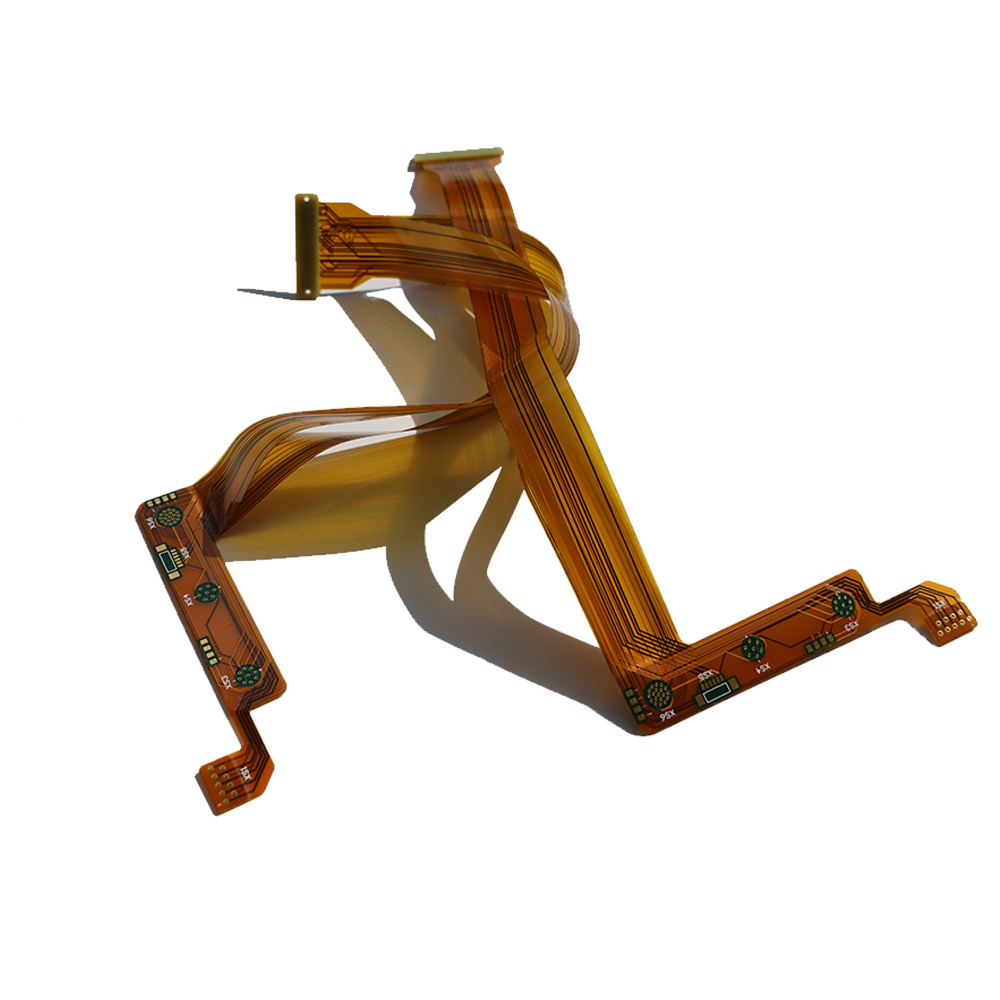

1. Wearable medical devices that are prone to wear and tear

At present, the market for wearable medical devices for patients is growing at a rate of over 16% per year. In addition, medical devices are becoming smaller, lighter and easier to wear without affecting accuracy or durability. Many such devices use online motion sensors to compile relevant data and then forward this data to appropriate healthcare professionals. At present, the top medical devices on the market are already very powerful, and some can even detect when a patient's wound is infected. The implementation of these functions relies on the design innovation of the researchers behind it, as well as the technical support for the PCB manufacturing industry.

With the increasingly severe trend of aging population, elderly care will also become a growing market. Therefore, wearable medical devices are not limited to traditional medical industries, but will also become a major demand in the fields of home and elderly care as the aging population grows.

2. Implantable medical devices

When it comes to implantable medical devices, the use of PCB assembly becomes more complex because there is no unified standard that can make all PCB components comply. That is to say, different implants will achieve different goals for different medical conditions, and the unstable nature of implants can also affect the design and manufacturing of PCBs.

For example, by manufacturing precision PCB circuit boards, deaf and mute people can hear sound through cochlear implantation. And those who suffer from advanced cardiovascular disease can benefit from implanted defibrillators, and so on. So in this field, the PCB manufacturing industry still has higher efficiency to develop.

3. Medical devices for heart rate health types

In the past, the integration of heart rate health recording devices was very poor, and many electronic devices lacked all types of connections for recording. On the contrary, each system software is a direct system software that solves order information, text documents and other daily tasks in a separate way. With the passage of time, this system software has long been integrated, producing a more comprehensive interface, which has also promoted the pharmaceutical industry to increase the medical care of patients and further improve efficiency.

Application

Application of Medical Equipment

Medical equipment is one of the fields where PCBs are widely used. With the continuous development of technology, new products and technologies are constantly emerging in the field of medical devices, which promotes the continuous innovation and demand for PCBs. The following are some common medical devices that require the use of PCBs:

1. Medical imaging equipment: including X-ray machines, CT scanners, MRI imaging equipment, etc. PCBs are used to control imaging processes, signal processing, data transmission and other functions.

2. Pacemakers and rhythm managers: These devices are used to monitor the rhythm of the heart and provide electrical stimulation when needed to maintain normal heart rhythm.

3. Defibrillator: used to treat acute cardiac events such as sudden cardiac death, by releasing electrical energy to restore the normal rhythm of the heart.

4. Ventilators and artificial respiration equipment: used to treat respiratory system diseases or maintain the patient's respiratory function during surgery.

5. Blood pressure monitoring equipment: including blood pressure monitors, arterial blood pressure monitors, etc., used to measure the patient's blood pressure.

6. Blood pressure monitor: it is used to detect the blood pressure level of patients, which is crucial to the management of diabetes patients.

7. Surgical instruments and surgical navigation equipment: including surgical knives, surgical robots, navigation systems, etc., used for various types of surgeries.

8. Medical testing instruments: including blood oxygen meters, electrocardiographs, heart rate meters, etc., used to monitor the physiological parameters of patients.

9. Drug delivery equipment: including drug pumps, infusion equipment, etc., used to accurately control the delivery speed and formula of drugs.

10. Ear, nose and throat equipment: including hearing aids, sinusoscopes, etc., used for the diagnosis and treatment of ear, nose and throat diseases.

11. Rehabilitation equipment: including electric wheelchairs, orthotics, etc., used to help people with disabilities recover their mobility.

12. Medical laboratory equipment: including analytical instruments, testing equipment, etc., used for clinical experiments and diagnosis.

If you have any questions or needs regarding PCBA technology for medical devices, please feel free to contact us at any time. RICHPCBA will be dedicated to providing you with professional support and solutions. May we work together towards the development of medical technology, benefiting human health!